Introduction: The Unseen Engine Driving Modern Vehicles

Consider any contemporary car cruising along the roadway—be it the sleek profile of a gas-powered grand tourer or the sleek, silent, and aerodynamic shape of the newest electric wonder. We observe smooth paint, shiny chrome, and new design. But behind that skin is a universe of complexity, a mechanical world by thousands of individual automotive parts. Every component, from the biggest engine block to the tiniest valve, has to fit and operate with aprecisionthat is almost absolute. It is a world measured not in inches or centimeters, but in microns. This is the world of precision machining, the invisible engine that truly powers modern vehicles and a cornerstone of the automotive manufacturing landscape.

Precision machining is not just a manufacturing process; it is the foundational craft that makes the performance, safety, and efficiency we expect of our cars possible. The use of precision is the unspoken assurance that a piston will cycle perfectly billions of times, that a gear will transmit torque without failure, and that a brake caliper will apply force with unquestionable reliability. Without it, the engineering blueprints that promise revolutionary horsepower or long battery range would be just that—a presuming promise on paper. This article is your ultimate guide to this important field within the manufacturing industry. We will travel through the core technologies that characterize the process to the trends that will transform it in the future, providing a full picture of how carefully designed metal and polymer turn into the spine of the automotive industry.

What is Precision Machining in the Automotive Context?

Machining to the layman may bring to mind sparks flying off a manually operated lathe, a skill more of art than science. Although the craft of a master machinist remains priceless, contemporary automotive precision machining is a much more advanced undertaking. It is the science of removal; a very precise procedure that involves the application of sophisticated equipment to selectively remove material from a workpiece, shaping it into a final product that meets the most stringent quality standards.

It is not merely a matter of cutting metal. It is about attaining a degree of precision and uniformity that could never be duplicated by human hands on a mass basis. The entire production process is governed bycomputer numerical control (CNC), where digital designs—CAD (Computer-Aided Design) models—are converted into instructions that are used to control automated tools. The use of computer-driven numerical control dictates every movement, every cut, and every rotation, so that the thousandth part made is dimensionally the same as the first. This machining process is a procedure in which the margin for error is usually smaller than the wavelength of visible light, a testament to its high accuracy.

Core Technologies: The Power Trio Driving the Industry

*Our CNC milling process maintains exceptional precision.

Although the automotive sector is enormous, a trio of advanced technologies form the powerhouse of contemporary automotive machining. They have different capabilities that are specific to certain challenges.

- CNC Machining (Milling and Turning): CNC milling is a process that cuts material with a rotating tool on a fixed workpiece, which is suitable when the shape or cavity is complex such as engine parts. CNC turning rotates the workpiece against a stationary tool, which is ideal with cylindrical components such as crankshafts and axles. Most automotive parts are produced through these processes.

- Multi-Axis Machining (5-Axis): In contrast to the three-axis CNC machines, 5-axis machining introduces two rotational axes, which enable the machine to make precise cuts at any angle in a single set up. This minimizes lead time, enhances accuracy and allows the manufacture of complex components such as turbine impellers and suspension knuckles.

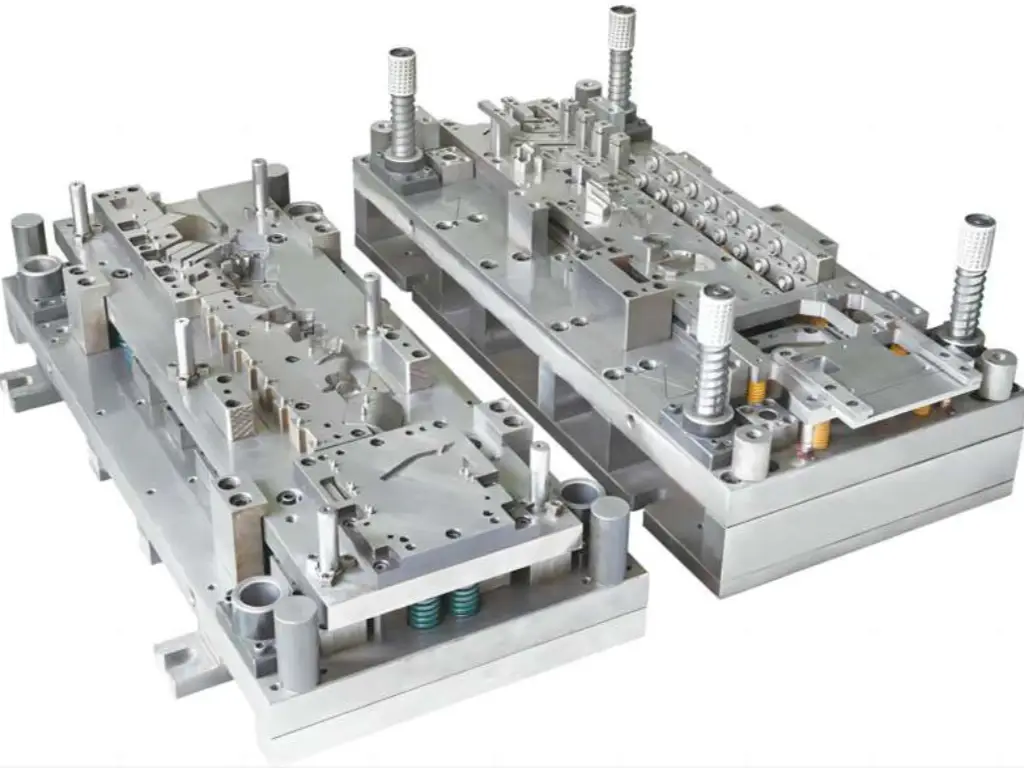

- Electrical Discharge Machining (EDM): EDM is a process that removes material by using controlled electrical sparks to cut hard-to-cut or complex parts. It is ideal to make sharp internal corners and complicated molds in plastic injection and die casting, which are critical in the production of tooling in the automotive sector.

Beyond Dimensions: Understanding Tolerance, Repeatability, and Surface Finish

To an automotive engineer or a procurement specialist, the blueprint of a part is a language of precision. There are three key terms:

- Tolerance: This is the allowable range of deviation of a given dimension. A specification may be written as 25mm +/- 0.01mm, which means that the final dimension must fall between 24.99mm and 25.01mm. Automotive applications do not allow any compromise on tight tolerance requirements. An example is the clearance between a piston and its cylinder wall, which is a closely controlled gap that determines engine efficiency, oil consumption, and overall life.

- Repeatability: This is a measure of how well a machine can make parts within the specified tolerance over a complete production run. It is easy to produce one perfect component; it is another thing to produce 10,000 of them. A mature, quality-controlled machining process is characterized by high repeatability, which is a requirement of reliable automotive production and ensures consistent part quality.

- Surface Finish (Ra): This measures the smoothness and texture of a machined surface. It is not only aesthetics. A bearing journal with a smooth surface minimizes friction and wear, which prolongs the life of an engine. A thin film of oil is retained by a precisely textured surface inside a cylinder bore to provide lubrication. Alongside precision grinding, controlling surface finish is a critical performance feature, just as important as the physical dimensions of the part.

The Backbone of Every Vehicle: Critical Parts Made by Precision Machining

*This video shows how car engine part prototypes are made using CNC machining.

Precise machining does not just apply to a single section of a vehicle; it is the skeleton of structure and functionality of almost all major systems. It has as many applications as the automobile itself.

Powertrain System (Internal Combustion & Hybrid): This is the core of the conventional car, where exceptional accuracy is the key.

- Engine Block & Cylinder Head: The basic blocks, machined for flatness, accurate bore diameters, and intricate coolant/oil channels.

- Crankshaft & Camshafts: These rotating parts are machined and ground to extremely tight tolerances to balance, bearing journal size and lobe profile to provide smooth operation and proper valve timing.

- Pistons & Connecting Rods: Transmission components and engine parts machined to exact weight, dimension, and balance to endure millions of cycles under extreme pressure and heat.

Transmission System:

- Gears & Shafts: Gear teeth profiles and shaft diameters are machined to the highest quality standards to provide quiet, efficient torque transfer and low wear.

- Transmission Case & Valve Body: These complicated housings are machined on multiple axes to produce complex hydraulic passages and mounting locations that control automatic gear changes.

Chassis and Suspension System:

- Brake Calipers & Rotors: Safety-sensitive parts that are machined to ensure the piston bores are precise and the rotor surfaces are flat to ensure smooth and reliable braking.

- Steering Knuckles: Complicated components that join the suspension, wheel hub, and steering linkage, and must be machined in multiple axes to be strong and geometrically precise.

The Electric Vehicle (EV) Revolution: EVs are mechanically simpler in certain aspects, but the introduction of each new model brings a new set of parts that require high-precision production.

- Electric Motor Housings: Machined to tight tolerances to provide correct alignment of the rotor and stator, which is essential to motor efficiency and noise suppression.

- Battery Trays & Enclosures: These can be large, complicated aluminum structures that need to be lightweight but extremely strong to protect the battery cells. Reducing the overall vehicle weight is key, and they need a lot of machining to provide mounting points and sealing surfaces.

- Thermal Management Systems: The complex channels are machined into components such as cooling plates and heat sinks to remove the vast amount of heat produced by batteries and power electronics.

The Future is Now: Key Trends Shaping Automotive Machining

The road ahead for automotive machining is being paved by transformative trends. Standing still is not an option; the industry is evolving at a rapid pace, driven by electrification and digitalization.

The Impact of Electrification (EVs) on Machining Demands

The shift to electric vehicles is not just a powertrain swap; it’s a paradigm shift for manufacturing. This transition introduces new challenges and opportunities forprecision machining. The immense pressure for lightweighting to maximize battery range means a greater reliance on machining aluminum alloys and even composites. The focus on thermal management has created a surge in demand for complex cooling components. Furthermore, the high-RPM nature of electric motors requires superior balance and dimensional stability, pushing tolerances to new levels. This is where a dedicated automotive machine shop excels.

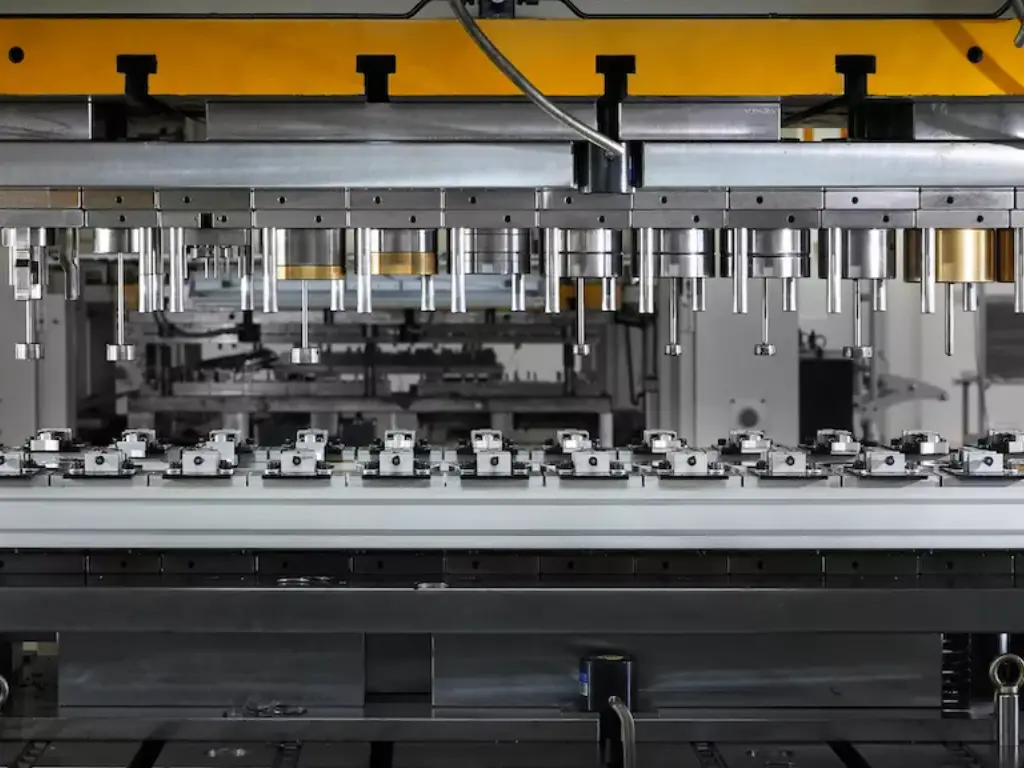

Smart Manufacturing: How Industry 4.0 is Optimizing the Process

The Fourth Industrial Revolution is here, and it’s making factories “smart.” Data-driven manufacturing is transforming the shop floor. Sensors in machining centers monitor everything from tool wear to real-time pressure. This data enables predictive maintenance, allowing technicians to replace a tool moments before it fails. Automation is integrated into quality control, creating a closed-loop system for continuous improvement. This digital nervous system, incorporating lean strategies, results in unprecedented production efficiency, quality, and traceability, all while reducing material waste.

Choosing the Right Materials: From Steel Alloys to Advanced Composites

One of the most critical decisions that are made long before the first chip is cut is material selection. It is a compromise between strength, weight, cost and manufacturability. The automobile industry uses a variety of materials, each of which is selected based on its properties. The following is a list of typical automotive materials and their main characteristics:

| Material Type | Examples | Key Benefits | Typical Applications |

| Aluminum Alloys | 6061, 7075 | High strength-to-weight ratio, corrosion resistance | EV battery enclosures, suspension components |

| Steel and Steel Alloys | 4140, Stainless Steel | High strength, durability, cost-effectiveness | Crankshafts, gears, structural parts |

| Titanium Alloys | Various aerospace grades | Strength comparable to steel, lightweight, excellent heat and corrosion resistance | High-performance and motorsport applications |

| Engineering Plastics & Composites | PEEK, Delrin | Lightweight, low friction, good mechanical strength | Prototypes, interior trim, low-stress mechanical parts |

Knowing the advantages and compromises of each type of material, engineers can maximize performance and cost in automotive design.

How to Choose Your Precision Machining Partner: A Checklist for Success

Choosing the right partner is not just a procurement decision; it is a strategic decision that has a direct effect on your product quality, production time, and profitability. A poor supplier may turn into a bottleneck. The following is a checklist to assist you in vetting and choosing a world-class machining partner:

- Technical Ability and Equipment: Do they have the right equipment? Do they have sophisticated CNC technology like 5-axis machining and EDM, which are signs of the capability to work with complex geometries?

- Quality Management & Certifications: This is a must. The partner should possess strong quality systems. Seek IATF 16949 certification, which is the international quality standard in the automotive sector, proving they can meet strict quality standards.

- Materials Expertise: Are they capable of working with the materials your project needs? An excellent partner has many years of experience machining a variety of automotive materials.

- Project Management & Communication: How will they handle your project from quote to delivery? Seek a partner that has a committed project manager and a transparent system to ensure high customer satisfaction.

- Proven Automotive Experience: Have they done it before? A partner with a proven track record understands the special pressures and demands of the industry and can meet your specific needs.

An effective precision machining partner is not merely a vendor, but a part of your team. Understanding what is precision machining is essential before selecting the right long-term machining partner. Through a close assessment of candidates based on this checklist, you reduce risk and establish the basis of long-term success. Seek a partner that not only fits the technical requirements but also fits your quality, communication, and innovation commitment. Industries like healthcare rely heavily on precision medical machining to meet stringent performance and safety requirements. The correct decision made now can propel operational excellence and competitive advantage in the years to come.

Why Automotive Leaders Trust U-Need as Their Machining Partner

Pin Gauges

Profile Projector

Height Gauge

Push-Pull Tester

Circular Runout Gauge

2.5D Vision Measuring Machine

Coordinate Measuring Machine

Micrometer

Hardness Tester

U-Need has more than 30 years of experience in precision machining and applies it to the automotive industry, including the fast-growing new energy vehicle (NEV) industry. With an average of 15 years of practical experience, our team of engineers has provided more than 35,000 unique non-standard parts to more than 300 customers in 20+ countries. We have a world-class Japanese and Swiss machinery, and an end-to-end production line that includes turning, milling, grinding, EDM, and stamping, which makes us fast and flexible. Our lead times are as low as 3-5 days and we can support urgent, high-mix low-volume orders, which enables our automotive customers to shorten development cycles and remain at the forefront.

Our expertise is in custom, high-performance components that meet the demanding automotive applications. Our material portfolio includes more than five types of metal, 12 engineering plastics, ceramics, and silicone, whether stainless steel fasteners or PEEK polymer bushings. We are also very skilled in micro-tolerance features like 0.02mm chamfers and ultra-thin mold inserts, with our machining accuracy at ±0.001mm.

The real difference maker at U-Need is our integrated process and engineering-based optimization. Whether it is PG optical grinding and mirror EDM polishing, multi-process compound machining, or custom heat treatments, all processes are quality-controlled and traceable to the ISO 9001:2015 standards. Our QC process is three-stage and guarantees a 99.3 percent pass rate with the support of sophisticated inspection equipment such as CMM and 2.5D projectors. We are all about full customization-MOQ of 1 piece, 20+ surface finishes, and 3-5 days rapid prototyping. We offer a smooth process of concept delivery with proactive technical assistance, real-time order tracking, and a one-year warranty.

Conclusion: Driving the Future of Automotive Performance, Together

The modern vehicle is a marvel of engineering, a complex machine whose very existence depends on the unseen, micron-level precision of its constituent parts. From the powerful heart of a combustion engine to the silent, efficient core of an electric motor, precision machining is the fundamental enabler of progress. It is the craft that translates ambitious designs into reliable, high-performance reality.

Common Applications of Automotive Parts

- Aftermarket Parts

- Fixtures

- Armatures

- Automotive Lighting Lamps

- Custom Auto Parts - Low-Volume Manufacturing

- Rapid Injection Molding for Aluminum and Steel Molds

- Auto Lamp Lens

- Assembly Line Components

- Plastic Dash Components

- Functional Prototypes for Mechanical Components

- Complex Functional Components for Testing

- Precision Machined Prototypes for Design Validation

As the industry accelerates towards an electric and increasingly autonomous future, the demands on precision machining will only intensify. The challenges of new materials, more complex designs, and ever-tighter tolerances will require partners who are not just suppliers, but true collaborators in innovation. The journey ahead is exciting, and it will be built, one precisely machined component at a time. At U-Need, we’re not just making parts — we’re driving the future of automotive performance. As your precision machining partner, we’re here to help you meet the demands of next-generation mobility, one meticulously crafted component at a time.