Contemporary aviation and space exploration are important engineering feats. Commercial airliners carry hundreds of passengers across continents every day, and orbital satellites relay the information that is vital to global communication. These are complicated machines in which the integrity of each component is critical. Every one of the aerospace components, no matter how small, is important in maintaining operational integrity. The breakdown of one of these aircraft parts may be disastrous. Aerospace precision machining is the discipline that is involved in the production of these components with the necessary level of precision. It is the basic manufacturing process that makes modern flight vehicles, from commercial jets to spacecraft, safe and perform as intended.

This guide will give a detailed description of this important area. We shall look at its underlying significance to flight safety and performance, the core technologies and advanced materials used, and the stringent quality standards that prevail in the aerospace industry. We shall also examine typical aerospace applications and look ahead to the future of this fundamental manufacturing science.

The Critical Role of Precision Machining in Aerospace

* Learn what you need to know for designing parts made for aerospace

The aerospace industry cannot do without precision machining. It is much more than just a simple manufacturing company, and it is the basis of safety, performance, and innovation in aviation and space exploration. Its important contributions are as follows:

- Absolute Safety Assurance: Precision machining provides the required tolerances and surface finishes to prevent any structural defects that may lead to catastrophic failures. In aerospace, safety can be jeopardized by microscopic flaws. Zero-error manufacturing is not a negotiable requirement and precision machining fulfills this requirement by converting design blueprints into very precise components with little margin of human error.

- Empowering Extreme Performance: Jet engine turbines and cryogenic fuel pump parts are examples of aerospace components that have to withstand high temperatures, pressure, and vibration. Complex geometries and aerodynamic surfaces that maximize fluid dynamics and thermal efficiency can be produced using precision machining, which is critical to the reliability of propulsion systems operating in harsh environments.

- Lightweight and Fuel-Efficient Design Driving: The drive towards fuel economy and payload maximization is based on the need to make aircraft lighter without sacrificing strength. This is possible through precision machining, which creates parts with optimized internal structures, usually milled out of solid billets. These parts are designed to be strong and discard all unnecessary weight, which helps in the overall fuel economy and sustainable aerospace design.

To sum up, precision machining is not only a technical necessity, but it is a pillar of aerospace advancement. It helps the industry to fly higher, faster, and more efficiently than ever before, protecting human lives and expanding engineering opportunities.

Core Technologies Driving Aerospace Machining

Cutting-edge machining technologies enable the extraordinaryprecision and complexity needed in the manufacturing of aerospace parts. These sophisticated processes convert digital designs into high-performance components that are aerospace-grade. The table below summarizes the main technologies that drive this development:

| Technology | Core Function | Key Advantages in Aerospace Machining |

| 5-Axis CNC Machining | Enables cutting from multiple angles by rotating around two additional axes (beyond X, Y, Z). | – Machines complex geometries (e.g., blisks, turbine blades) in one setup – Reduces re-fixturing and errors – Enhances accuracy and speed |

| Electrical Discharge Machining (EDM) | Removes material using controlled electrical discharges instead of physical cutting. | – Ideal for hard-to-machine alloys like Inconel and Titanium – Allows for intricate internal shapes – No mechanical stress on part |

These are the technologies that are the foundation of modern aerospace machining. They allow the production of very complex, long-lasting, and dependable parts that are crucial to the development of the industry by integrating mechanical accuracy with smart process control. Essentially, the aerospace industry would not have been able to meet the increasing demands of safety, performance, and innovation without the constant development and utilization of these fundamental technologies.

Advanced Materials: The Building Blocks of Modern Aircraft

The materials that constitute an aerospace vehicle are very crucial in determining the performance characteristics of the vehicle. Selection of a material is done following a critical analysis of its strength, weight, temperature resistance and cost. Such advanced materials present special machining problems that need special knowledge and equipment of the best aerospace manufacturers.

- Titanium Alloys: Titanium alloys are also known to possess high strength-to-weight ratio and good corrosion resistance and are widely used in airframes, engine components and fasteners. They are difficult to machine because of their low thermal conductivity, where heat builds up at the cutting tool edge. This necessitates some cutting speeds, feed rates and cooling techniques to manage the heat and prevent premature tool wear.

- Inconel & Superalloys: These are superalloys based on nickel and are applied in high-temperature applications due to their ability to retain strength in the heat of the hot section of a jet engine, which is found in both commercial and military aircraft. The same property makes it very difficult to machine. They are prone to work-harden during cutting and generate high tool pressure, requiring very rigid machines, including high-powered lathes and mills, and special cutting tool materials.

- Aluminum Alloys: Aluminum is a significant aerospace material due to its low density, formability, and low cost. It is commonly used on fuselages, wing structures, aircraft doors and other components. Aluminum alloys are generally more easily machined than harder alloys, but their relative softness can be an issue in holding tight tolerances and high-quality surface finishes without deforming the part. Stainless steel, valued because of its strength and resistance to corrosion, and copper alloys in connectors and electrical parts such as bushings are other common materials.

- Composites & High-Performance Plastics: Composites like carbon fiber reinforced polymer (CFRP) are very stiff and strong but at significantly lower weight than metals. Metal machining is not composites machining. It involves the cutting of abrasive fibers and a polymer matrix, which can cause delamination of the material and generates fine and hazardous dust. This requires special diamond coated tooling and effective dust extraction systems.

These materials are not merely the physical framework of an aircraft, but are also the major facilitators of performance, safety and efficiency during flight. They require not only the proper choice of material to use but also the advanced machining techniques that are needed to handle them. The end result is that material science and precision manufacturing have come together to enable modern aircraft to fly further, faster and more reliably than ever before.

Uncompromising Quality: The Standards and Tolerances

Quality is a core component in the aerospace industry that is incorporated in every process to meet stringent specifications. This is institutionalized by a system of standards, certifications, and verification processes that govern the whole manufacturing lifecycle, overseen by bodies like the Federal Aviation Administration (FAA).

The Gold Standard: Understanding AS9100 Certification

AS9100 is the global Quality Management System (QMS) standard of the Aviation, Space, and Defense (AS&D) industry. The standard builds on the ISO 9001 requirements and introduces many more requirements that are specific to the critical nature of the global aerospace industry.

AS9100 requires an extensive system that institutionalizes quality within an organization. The most important requirements are:

- complete traceability (documenting the history of a part, including raw material and all manufacturing processes),

- effective risk management (identifying and mitigating possible failures),

- rigorous configuration management (aircraft components must be made to the correct design revision),

- a commitment to continuous improvement.

As a customer, choosing an AS9100-certified supplier gives assurance that that organization has a disciplined, repeatable, and accountable manufacturing process.

Achieving Tight Tolerances: The Role of Metrology and Inspection

Tolerance is the acceptable variation of a physical dimension. These tight tolerances are commonly specified in microns (µm) in aerospace. Such stringent dimensional requirements are required to make sure that components like bearings and fittings fit together and operate as designed under operating loads.

The science of measurement, metrology, is concerned with verifying that parts meet these tolerances through robust quality control. The Coordinate Measuring Machine (CMM) is a major tool in contemporary quality inspection. A CMM has a very precise probe that measures thousands of points on the surface of a component, producing a very precise three-dimensional data set. This information is then compared directly with the original CNC CAD model to check conformance. It is a thorough verification process that gives objective data, and it is certain that all features are dimensionally accurate and within the tolerance. This is the last check that verifies a part is ready to be used in a demanding aerospace project.

Common Applications of Aerospace Precision Machining

Critical components of all major systems of modern aircraft and spacecraft are manufactured by precision aircraft CNC machining to produce precise parts, including clamps. Its wide use can be exemplified as follows:

| Application Area | Examples of Machined Components |

|---|---|

| Engine Parts | Engine Parts Turbine blades, compressor blades, blisks (bladed disks), engine shafts, and casings that are able to withstand high temperatures and forces. |

| Structural Parts | Wing spars, wing ribs, fuselage bulkheads, and connection fittings all play an important role in the structural integrity and aerodynamics of the aircraft. |

| Landing Gear Systems | Strong steel and titanium components that are able to withstand the stress and impact of landings, such as struts, actuators, and trunnions. |

| Satellite & Spacecraft Components | Satellite buses, propulsion components, sensor mounts, and protective housings for electronics- optimized to weight, reliability, and durability in harsh environments. |

In conclusion, aerospace precision machining is fundamental to ensuring the performance, safety, and longevity of critical components across aircraft and spacecraft systems. To explore applications in greater depth, read our expert guide on precision machining for aerospace parts. As technology advances, its role will only become more pivotal in driving innovation and reliability in the aerospace industry.

Why Partnering with U-Need Elevates Your Project

- Aircraft Engine Components

- Structural Components

- Custom Aerospace Parts

- Rapid Prototyping for Aerospace Systems

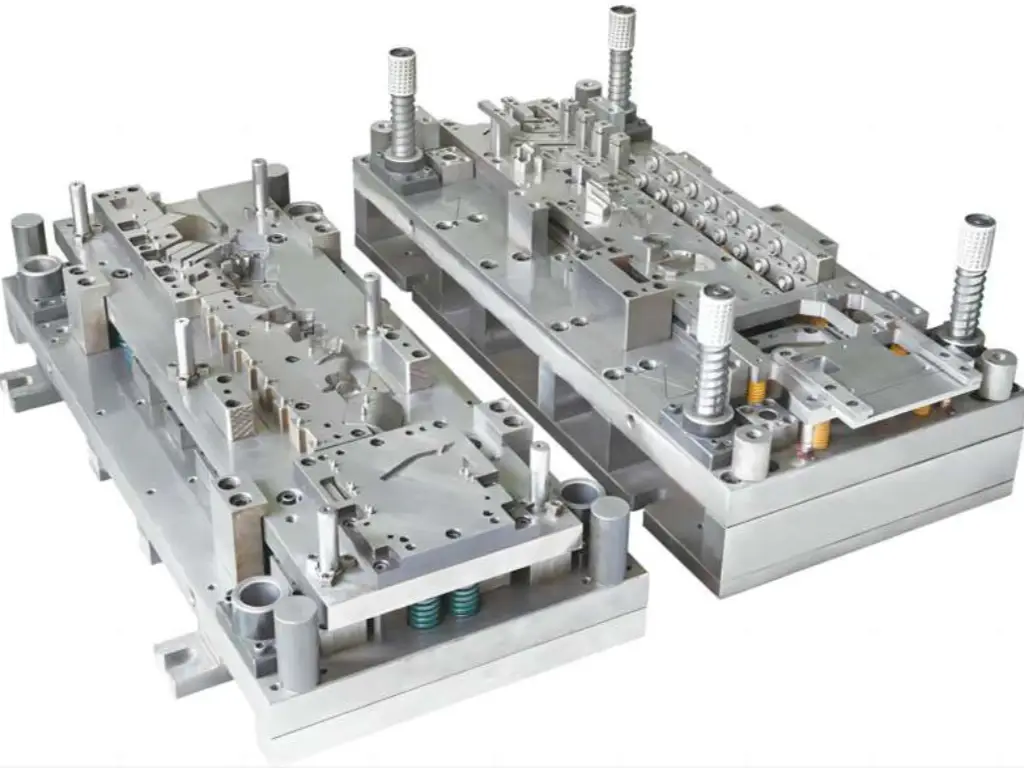

- High-Precision Molds for Aerospace Applications

- Avionics Components

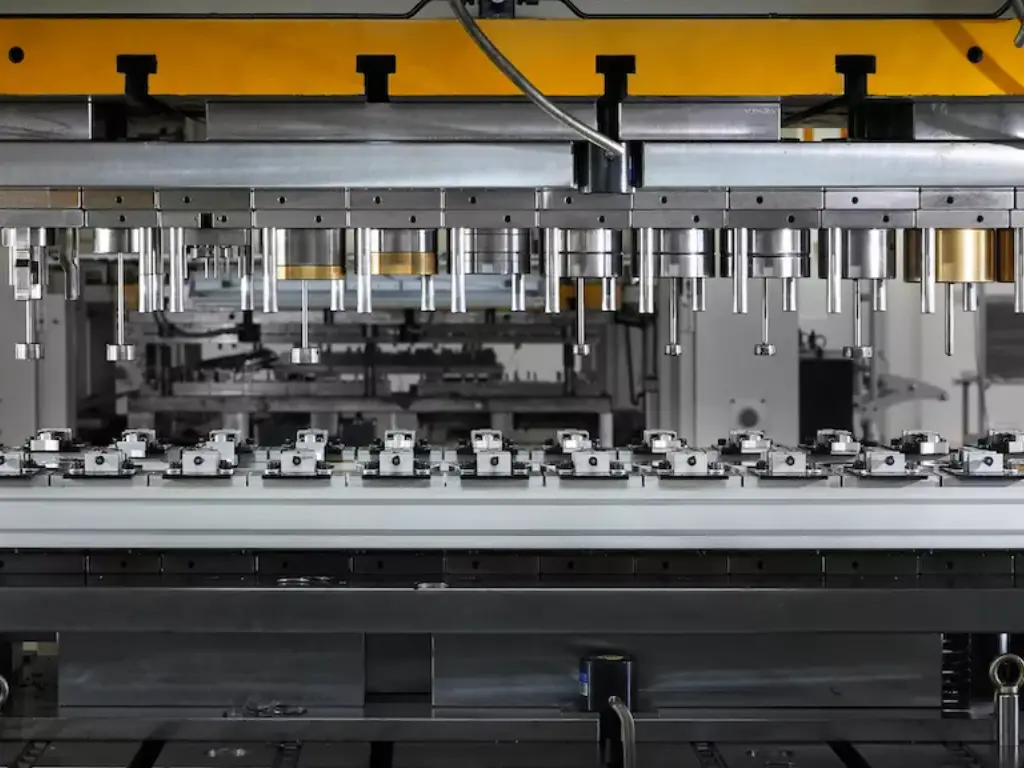

- Assembly Line Components for Aircraft

- Functional Prototypes for Aerodynamic Testing

- Complex Functional Parts for Spacecraft

- Precision Machined Prototypes for Design Validation

- High-Strength Fasteners and Connectors

- Thermal Management Solutions for Aerospace

At U-Need, we understand that in aerospace and high-precision industries, the margin for error is often measured in microns—and the cost of downtime, in millions. That’s why we’re not just another parts supplier. We’re your strategic manufacturing partner, built on over 30 years of hands-on precision engineering experience. Our team—averaging 15+ years in the field—knows what it takes to meet the uncompromising standards of over 300 global clients across 20+ countries. From mission-critical mold components to custom device fittings, we don’t just meet specs—we help redefine what’s possible.

What sets U-Need apart is our ability to turn complexity into clarity. Whether you’re working with high-performance plastics like PEEK, difficult-to-machine metals like tungsten carbide, or requiring tolerances as tight as ±0.001mm, we bring unmatched expertise to the table. Our deep understanding of multi-process integration—like PG optical grinding, EDM mirror discharge, and micron-level polishing—means we can deliver what others won’t even quote. And thanks to our agile workflow and standardized digital management, we deliver prototypes in as fast as 3–5 days without compromising quality.

Partnering with us means more than access to advanced capabilities—it. It means peace of mind. We offer full-spectrum customization with no minimum order quantity, rapid technical communication, and a rigorous three-level quality control process backed by ISO 9001:2015. From design co-creation to post-delivery support, we take ownership of every step—so you can focus on innovation, while we make precision happen.

The Future of Aerospace Precision Machining

The aerospace precision machining industry is in a revolutionary period. With next-generation aircraft pushing the boundaries of speed, range, and complexity, manufacturing must evolve in lockstep. The integration of additive technologies such as 3D printing with conventional processes like aerospace CNC machining—a hybrid manufacturing approach—now enables the creation of components with internal geometries once considered unmachinable. Machine learning and AI are optimizing tool paths, automating quality checks, and predicting maintenance needs with growing accuracy. Meanwhile, the Industrial Internet of Things (IIoT) is generating real-time data across production floors, transforming traditional workshops into smart, responsive manufacturing ecosystems. Together, these technologies are expanding the horizons of precision machining—and redefining what is possible.

At U-Need, we see ourselves as part of that future. Our engineering team continuously explores new materials and evolving tolerance strategies to stay ahead of aerospace industry demands. We are constantly refining intelligent workflows—from rapid-response digital quoting to consistent process data management—to ensure efficiency at every stage. Whether you’re focused on precision aerospace components or complex custom assemblies, we bring your ideas to life with speed, confidence, and deep expertise in aerospace CNC machining.