Precision is not an objective in the modern manufacturing industry, but rather a necessity. It is the capability to manufacture multi-faceted components with high precision, speed, and accuracy that makes the market leaders stand out from the crowd. The key to this ability is a technology called CNC. Although the acronym is widely used in technical communities, the meaning behind it and the process of transformation it embodies is frequently perceived at face value. The guide can be used to give a detailed overview of CNC, its essence, and the real-world implications of its implementation in high-stakes sectors. We will look at the process, the technology, and the criteria required to exploit it successfully.

CNC: Unpacking the Acronym and Core Concept

CNC is an abbreviation of Computer Numerical Control. In its purest form, this term refers to a high-tech and automated production process in which computer software that is already programmed directs the flow of factory tools and machinery. The computer, which is the controller, converts a digital design into a particular set of instructions that direct the machine tools, which may be lathes, mills, grinders, or routers, to do their work with minimal human intervention.

In order to understand the revolutionary nature of CNC technology, it is helpful to compare it with conventional manual machining. Before CNC, a machine tool would be operated directly by a skilled machinist by turning levers, wheels, and buttons. This was purely a matter of skill, experience, and concentration of the operator. However, the ability to consistently produce high-quality parts was limited by the operator’s skill, experience, and concentration. There was a high risk of human error, it was extremely hard to achieve a high degree of consistency in several parts, and the pace of production was limited by the physical capacity of the operator.

Computer Numerical Control essentially eliminates these constraints. CNC guarantees an unprecedented degree of repeatability by automating the movements of the machine. The initial part made is the same as the hundredth or the thousandth, which is a critical consideration in mass production and in industries where interchangeability of components is a non-negotiable condition. This automation enables CNC machines to run around the clock, which significantly enhances output.

Subtractive manufacturing is the basic principle of the CNC manufacturing process. In this technique, a workpiece or blank is a solid block of material that is initially cut into shape to produce the final shape. All subtractive processes include cutting, drilling, boring, and grinding. A CNC machine performs these operations with great accuracy and cuts a completed product out of the original block according to the programmed instructions.

This is the complete opposite of the idea of additive manufacturing, which is also referred to as 3D printing. The additive process is used to construct an object by adding material in layers until the final shape is formed. Although CNC and additive manufacturing are both potent tools to convert a digital file into a tangible item, they differ radically in their approach, the type of material to work with, and the kind of tasks that they are most effectively applied to.

| Feature | CNC Machining (Subtractive) | 3D Printing (Additive) |

| Core Principle | Material is removed from a solid block. | Material is added layer by layer. |

| Materials | Metals (Aluminum, Steel, Titanium), Plastics, Wood, Composites. | Primarily Plastics, Resins, some Metals (powdered). |

| Precision | Very high; can achieve micron-level tolerances (±0.001mm). | Good, but generally lower than CNC for fine features. |

| Surface Finish | Excellent, can be very smooth directly from the machine. | Often shows layer lines, may require post-processing. |

| Ideal For | High-strength functional parts, prototypes, molds, and mass production. | Complex internal geometries, rapid prototyping, custom one-offs. |

| Waste | Produces chips and scrap material. | Minimal waste, uses only the material needed for the part. |

From Digital Design to Physical Part: The CNC Process

The process of converting an idea into a physical, highly precise engineered part through CNC is a multi-phase, organized process. It is a process that connects the digital design and the physical reality such that the final product is a direct and precise representation of the original purpose. This automated manufacturing process can be subdivided into four steps.

1. The CAD File: The Digital Blueprint.

It starts with the world of design, with CAD software (Computer-Aided Design). A two-dimensional (2D) or three-dimensional (3D) model of the final part is developed by the engineers and designers. This computer model is the master plan, which contains all the geometric details, dimensions, and characteristics required by the component. It is the ultimate truth of the whole manufacturing process. These are the contemporary developments of the old technical drawings, with much more detail and flexibility.

2. CAM Software: Design to Instructions.

After completion of the CAD model, the digital file is transferred to CAM software (Computer-Aided Manufacturing). The CAM software is an important intermediary, a translator. It reads the geometry of the CAD model and produces the toolpaths that the CNC machine needs to follow to make the part. The CAM programmer will define important parameters like cutting speeds, feed rates, choice of tool, and order of operations. This is called CAM programming, and it actually develops the manufacturing strategy. The computer program delivers this strategy in a certain form of programming language.

3. G-Code: The Language of Machining

The CAM software produces a text script referred to as G-code (also called a part program or machining code). Computer Numerical Control uses the standard language G-code, which gives the machine controller the specific instructions to follow. It is a sequence of alphanumeric instructions that guides all the actions of the machine. As an example, certain codes tell the machine where to travel in the Cartesian coordinate system (X, Y, and Z axes), the speed at which to travel, the tool to use, and when to switch on or off auxiliary systems such as coolant. The code of instructions is absolute and complete.

4. Machine Execution: The Automated Process

The G-code file is uploaded into the controller of the CNC machine. After the program has been launched, the machine takes over. It carefully follows the G-code instructions step by step. The machine is powered by strong servo motors that move the parts of the machine, including the spindle that carries the cutting tool and the table that carries the workpiece, to their exact locations. The machine continues the subtractive process, cutting, drilling, or grinding the material until the final part is finished. The CNC operator is no longer required to operate the machine directly by hand but rather to oversee, set up, and control the quality of the process and ensure that the final parts are of the specified quality.

Exploring the Types of CNC Machining Processes

The term CNC machine is not a unit; it refers to a broad category of sophisticated machinery, each of which is dedicated to a particular operation and material. The machine used depends on the geometry of the part, the tolerances needed, and the material being machined. In the general category of manufacturing, there are a few typical examples of CNC machines that are the foundation of contemporary manufacturing. An advanced manufacturing partner will most likely possess a wide range of these advanced machines to manage the production of various parts in a single roof.

CNC Milling

One of the most common machining processes is CNC milling. It is a multi-point cutting tool that rotates and moves in several axes to cut a workpiece that is stationary. CNC mills are extremely flexible and can cut a very large range of features, including simple flat surfaces and slots, as well as the detailed surface contours needed to make molds and aerospace components. Multi-axis mills (including 4-axis and 5-axis machines) can tilt both the tool and the workpiece at the same time, allowing the production of very complex designs in one machine.

CNC Turning

In CNC turning, the workpiece is held on a chuck and turned at high speed with a fixed single-point cutting tool passing over its surface. Cylindrical parts with external and internal features (shafts, pins, and rings) are produced using this process. The most common machines used in turning are CNC lathes. Rotating tools can also be used in modern turning centers to do secondary milling and drilling operations, producing more complex parts without having to transfer them to another machine.

Electrical Discharge Machining (EDM)

Electrical Discharge Machining is a non-traditional machining process that utilizes thermal energy rather than mechanical force. It is a process that eliminates material by a sequence of high-frequency, repetitive electrical discharges (sparks) between an electrode (the tool) and the workpiece, all of which is immersed in a dielectric fluid. EDM is especially useful when machining very hard metals such as tungsten carbide or when producing complex shapes, sharp internal angles, and deep and narrow holes that could not be made using traditional cutting tools. This is the basis of producing high-precision injection molds and stamping dies.

A full-service provider such as U-Need combines all of these core processes, including turning and milling, with more sophisticated grinding and EDM, to create complex parts in one, uninterrupted workflow. This combined method reduces the logistical complexity and provides the same quality control throughout the entire manufacturing process.

Beyond the Basics: Pushing the Limits of CNC Precision

In conventional production, a dimensional tolerance of +-0.05mm (or approximately 50 microns) can be regarded as adequate. But in the higher ranks of the manufacturing sector–in aerospace, medical equipment, semiconductors, etc.–this degree of accuracy is only a baseline. Real high-precision manufacturing is in another field, where tolerances are in single microns.

This search of extreme precision is not accidental; it is necessitated by utility. The distance between a turbine blade and its casing may be the difference between the efficiency and safety of an engine in a high-performance jet engine. In the case of a medical implant, a deviation of several microns may influence its biocompatibility and durability. In semiconductor manufacturing, the materials that are used to fabricate microchips must be precise to a degree that challenges the limits of physical reality.

This degree of accuracy is not an accident; it is the product of a planned policy of investment, skill, and process management. It goes beyond the normal capabilities of a CNC machine and needs a specialized ecosystem. In the case of U-Need, we have 30+ years of experience in precision components, and we have invested in the best equipment available in Japan and Switzerland, such as Takisawa lathes and GF AgieCharmille wire EDM machines. This enables us to maintain tolerances as tight as +-0.001mm (1 micron), a standard that more than 90 percent of the industry is unable to achieve.

This is made possible through special CNC technology and processes:

- Optical Profile Grinding (PG): PG machines are used in the most demanding applications, including semiconductor molds. They can work with materials as thin as 0.1mm and form internal and external corner radii as small as 0.02mm, all with a +-0.001mm tolerance.

- Mirror EDM and Polishing: In such industries as cosmetics, the surface finish of a mold is as important as its size. To obtain a real mirror finish (Ra ≤ 0.1μm), it takes a combination of specialized mirror EDM technology and the fine art of skilled technicians to polish by hand- a craft that combines high technology with human art.

This dedication to the extremes of accuracy shows a greater insight into production. It is the management of all variables, such as machine calibration and tool wear, thermal expansion, and material stability, so that the final component is not only within specification, but a true embodiment of the design.

CNC Applications in Demanding Industries

The real test of any technology is how it is used to solve real-world problems. The CNC manufacturing process has become an essential part of a variety of industries where failure is not an option and performance demands are absolute due to the high precision, repeatability, and versatility of the process.

- Aerospace: This sector requires lightweight and highly strong components, typically of exotic alloys such as titanium and Inconel. Everything, including complex turbine blades and engine components, structural airframe parts, etc., is manufactured using CNC machining with high-quality and safety standards.

- Medical Devices: The medical industry uses CNC due to its capability to cut biocompatible materials such as PEEK and medical-grade stainless steel to very fine tolerances, including custom surgical tools and orthopedic implants (knee and hip replacement), as well as miniaturized parts of diagnostic equipment.

- Automotive: CNC manufacturing is applied in the automotive industry to prototype new designs as well as in the mass production of high-value parts such as engine blocks, transmission shafts, and suspension parts. It is also essential to the custom needs of electric vehicles (EVs) and high-performance motorsports.

- Semiconductors and Electronics: The fabrication of microchips involves machinery and molds of microscopic precision. The ultra-precise parts of semiconductor manufacturing equipment, electronic connectors, and housings are also produced using CNC, and the precision is critical to their operation.

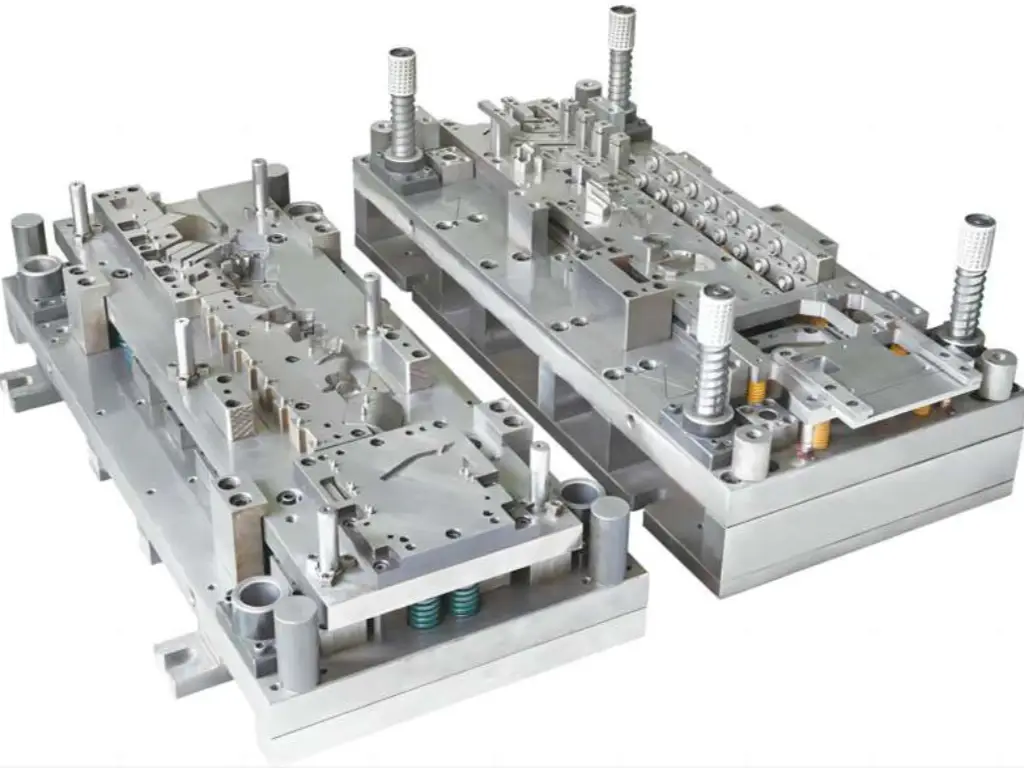

- Custom Mold and Tooling: One of the most important uses is perhaps in the production of tooling, dies, and molds used in other manufacturing processes (such as injection molding and metal stamping). The quality of the mold is the direct determinant of the quality of the thousands or millions of parts that the mold will produce. Much of the high-tech CNC manufacturing is the production of these custom mold components. Rather than discarding an entire costly mold when a part becomes worn, manufacturers turn to precision shops to get high-wear replacement parts. As an example, more than 60 percent of our output at U-Need is allocated to these parts in industries that utilize cold heading, injection molding, and stamping. Such replacement parts are usually more durable than original factory parts since they can be made using better materials or surface finishes.

| industry | Key Demands & Requirements | Example Applications & Components | Common Materials |

| Aerospace | Lightweight, high strength, extreme safety & quality standards. | Turbine blades, engine components, and structural airframe parts. | Exotic alloys (e.g., Titanium, Inconel). |

| Medical Devices | Biocompatibility, very fine tolerances, miniaturization. | Custom surgical tools, orthopedic implants (knee/hip replacements), parts for diagnostic equipment. | PEEK, medical-grade stainless steel. |

| Automotive | Prototyping, mass production, high performance, custom needs for EVs/motorsports. | Engine blocks, transmission shafts, suspension parts, custom EV/motorsport components. | Various metals & engineering plastics. |

| Semiconductors & Electronics | Microscopic precision, extreme accuracy for functionality. | Molds for microchip fabrication, ultra-precise equipment parts, electronic connectors, housings. | Highly dependent on the specific application |

| Custom Mold & Tooling | Quality determines the final product quality, high wear resistance, durability. | Tooling, dies, molds (for injection molding, stamping), high-wear replacement components (Over 60% of U-Need’s business). | Superior materials (e.g., Hardened tool steels) & surface treatments. |

What to Look for in a CNC Machining Partner

Selecting the appropriate CNC machining supplier is a very important choice that will directly affect the quality, cost, and time-to-market of your product. The technical abilities and business operations of your supplier may be the difference between a successful product launch and an expensive failure. In order to make a wise choice, one must compare the possible partners to a list of objective criteria.

Technical Capability and Equipment Portfolio

The first step is to evaluate the complexity and precision of the equipment needed in your project and determine whether the supplier can supply that equipment. A basic 3-axis mill cannot be used on a 5-axis aerospace component. Ask for a detailed list of their key equipment. Seek investments in well-known brands because this is usually a sign of a quality commitment. Make sure that what they claim to be able to do, especially in terms of the lowest possible tolerances, is consistent with the most challenging requirements on your technical drawings.

Demonstrable Engineering Expertise

The most effective machines are the ones that are operated and programmed by people. A real partner not only offers machining services, but also engineering value. A seasoned team can provide Design for Manufacturability (DFM) feedback, including recommendations on how to make changes to your design that may help to lower costs, enhance the strength of parts, or simplify the manufacturing process. Inquire about the experience level of their CNC machinist and engineering staff. A consultant supplier is much more useful than an order-taker.

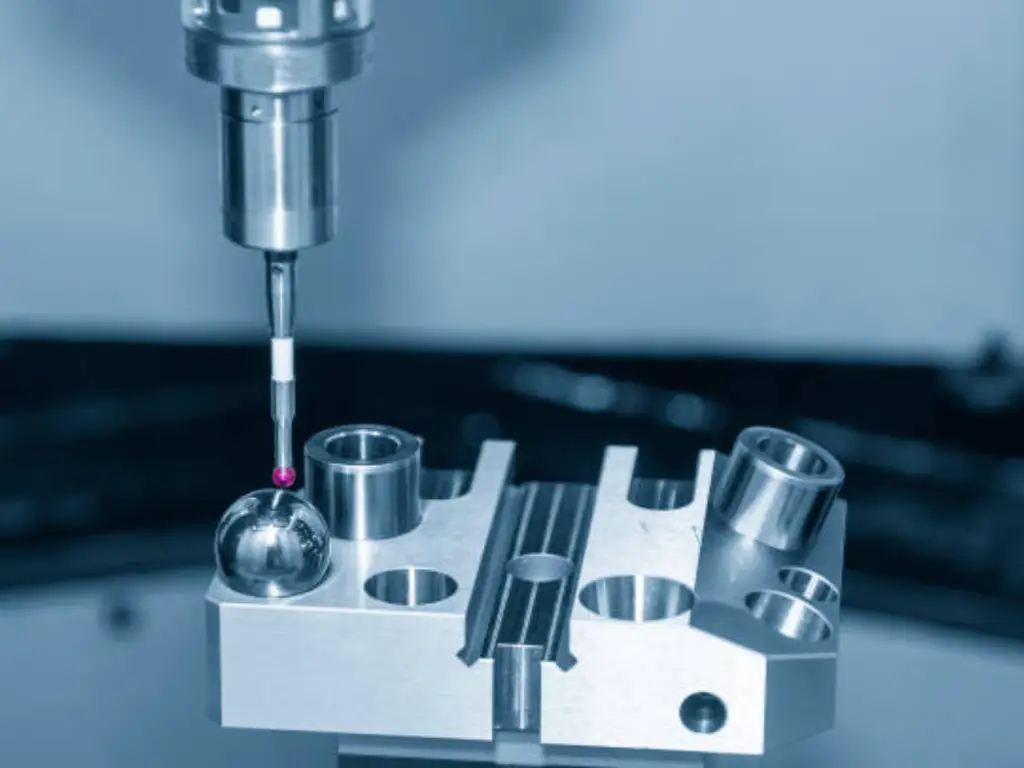

Robust Quality Management Systems

What do they do to ensure that the end product will be similar to the digital blueprint? There is no compromise when it comes to a strong quality control system. Find official certifications such as ISO 9001:2015, which indicates a dedication to standardized and repeatable processes. Enquire about their particular inspection processes. Do they have in-process checks at critical points and a final check-up? Ask about their metrology tools, including Coordinate Measuring Machines (CMMs) and 2.5D projectors, which are necessary to check complicated geometries and tight tolerances.

Transparent Communication and Project Management

Custom manufacturing projects need effective and transparent communication. Determine the responsiveness of a prospective partner in the quoting process. Do they pose clarifying questions to get to know your needs? A trusted partner will offer one point of contact and update you on the progress of your project at critical milestones. They are as competent in managing projects, meeting deadlines, and communicating proactively as they are in their technical skill.

When these standards are applied strictly, you will end up with a competent and trustworthy partner. We welcome this degree of examination at U-Need since our whole operation is designed to surpass these standards, including our constant investment in the best machinery in the world and our staff of engineers with an average of 15 years of experience.

Once you are prepared to work with a partner that shares this dedication to accuracy, we would like you to send your design files. Not only will you get a quote, but you will also be provided with a thorough technical consultation to show how our solution can add value and certainty to your project.