Metal stamping is one of the most basic and influential processes in the high-volume manufacturing world. Central to all this activity is one, brilliantly designed instrument: the metal stamping die. It is not just a machine, but the heart of a manufacturing system, a precision tool that is charged with the task of turning raw metal sheets into the working parts that drive our modern world through plastic deformation.

This authoritative text is a thorough examination of stamping dies. We shall discuss their basic definition, their essential uses in the major industries, the elements that make them up, and the major types that are in use in production today. We will also explore the metal stamping process itself, important design considerations, and the strategic considerations when selecting the appropriate tool to use on your project. Above all, we will discuss how to get the most out of the life and investment of these valuable assets, which is essential to any competitive manufacturing operation.

What Is a Metal Stamping Die?

A metal stamping die is a precision tool of a special nature that is used in a stamping press to cut, shape or form flat sheet metal into a certain, predetermined geometry or desired shape. The die is the heart of the cold-forming process and determines the final shape and precision of a completed part. It consists of a combination of specially designed parts, mostly hardened tool steel or carbide, which act together to accomplish one or more operations on each stroke of the press.

The main idea of a stamping die is to allow mass production with outstanding repeatability. In contrast to other processes, like CNC machining, which removes material in a step-by-step process to form a shape, sheet metal stamping forms or cuts the complete profile in one step or a rapid sequence of steps, often in a single stroke of the press. This is the basic difference that makes it an extremely efficient and cost effective way of manufacturing hundreds, thousands or even millions of the same parts.

The die does not produce the force, it is fitted into a larger machine, a mechanical or hydraulic stamping press, which supplies the tonnage required to cycle the die and work the material. The die is used to direct that energy with micron accuracy to create a part that fits all the design requirements. Simply put, the stamping die is the brain and hands of the operation, the muscle being the press, and it performs the complicated task of turning a flat sheet into a functional, three-dimensional metal workpiece.

Stamping Die Applications Across Industries

Stamping dies have an impact in nearly all areas of contemporary manufacturing. They are essential because they can create powerful, lightweight, and intricate components at high rates. The knowledge of these applications not only demonstrates the flexibility of technology but also how essential it is in products that we use in our daily lives.

- Automotive: The automotive sector is probably the biggest consumer of stamped metal parts. Dies are necessary in terms of structural elements as well as aesthetic panels.

- Body-in-White (BIW): Doors, hoods, fenders, roofs, and trunk lids are all large, complex components that are formed in huge transfer dies.

- Structural Components: A-pillars, B-pillars, chassis frames, and cross-members are stamped out of high-strength steel (HSS) and advanced high-strength steel (AHSS) to provide vehicle safety and rigidity.

- Brackets and Fasteners: Millions of smaller brackets to mount engines, exhausts, and interior parts are made in high-speed progressive dies.

- Aerospace: The production volumes are lower than in automobiles, but the precision, strength, and lightweighting are the most important factors.

- Airframe Components: Ribs, brackets and clips found throughout the fuselage and wing structure are commonly stamped out of aluminum and titanium alloys.

- Avionics and Housings: Sensitive electronic equipment and flight control systems are enclosed in enclosures that need EMI/RFI shielding, which is commonly done using carefully stamped metal cases.

- Seating and Interior: Aircraft seat and cabin interior components are required to be extremely light and yet extremely strong to pass the strict safety requirements.

- Electronics: Miniaturization has only added to the use of precision stamping.

- Connectors and Terminals: The small, delicate metal connectors that are in all electronic devices, including smartphones and servers, are produced in very complex progressive dies in large quantities.

- Casings and Enclosures: Laptops, tablets, and smartphones have metal frames and casings that are stamped to give them structural integrity and a high-quality feel.

- EMI/RFI Shielding: Shielding cans are stamped metal covers that are fitted over certain parts of a printed circuit board (PCB) to avoid electromagnetic interference.

- Appliances: In the case of consumer goods, mass production is the most important factor, and stamping is the process of choice.

- Housings and Panels: The exterior shells of washing machines, dryers, refrigerators, and ovens are large stamped components.

- Internal Framework: All the internal chassis and mounting brackets that hold motors, drums and other parts in place are all made using stamping dies.

- Control Panels: Control knob and display faceplates are metal and must be both functional and have a high quality surface finish.

- Medical Devices: This industry requires the utmost standards of cleanliness, accuracy, and biocompatibility.

- Surgical Instruments: A wide variety of disposable and reusable surgical instruments, including clamps, retractors, etc., contain stamped parts.

- Implantable Devices: Pacemakers and other implantable devices have their casings stamped out of titanium or stainless steel, and need burr-free finishing and complete reliability.

- Diagnostic Equipment: Large diagnostic equipment such as MRI and CT scanners have enclosures and internal parts that are stamped to form the structure.

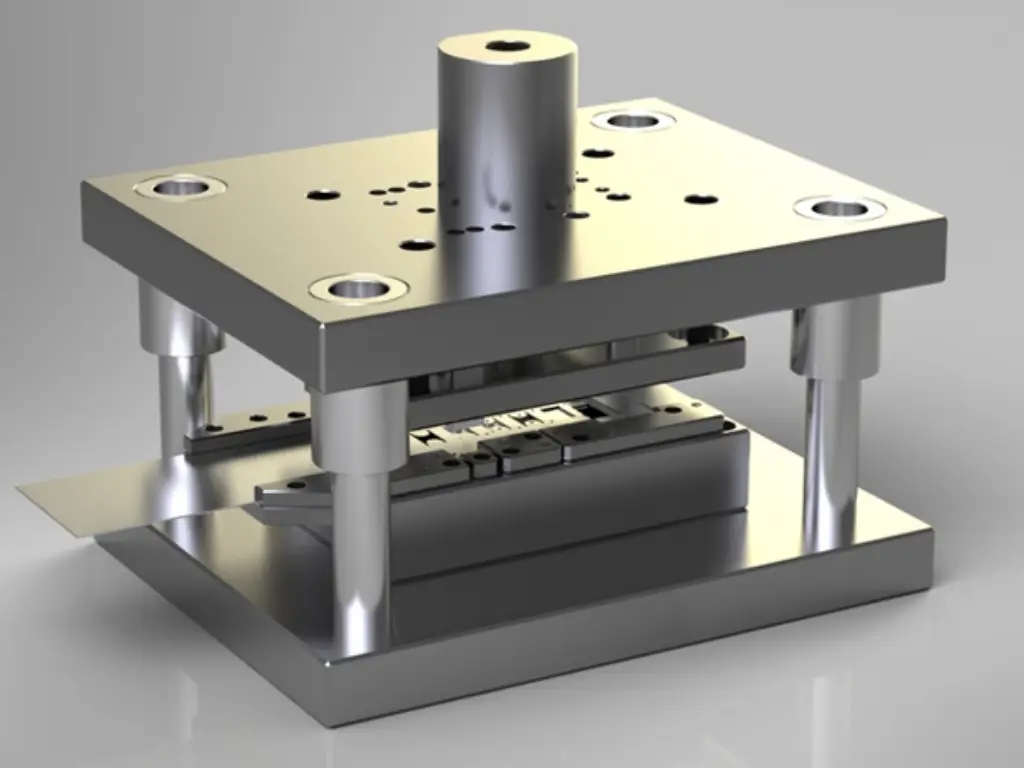

Core Components Inside Every Stamping Die

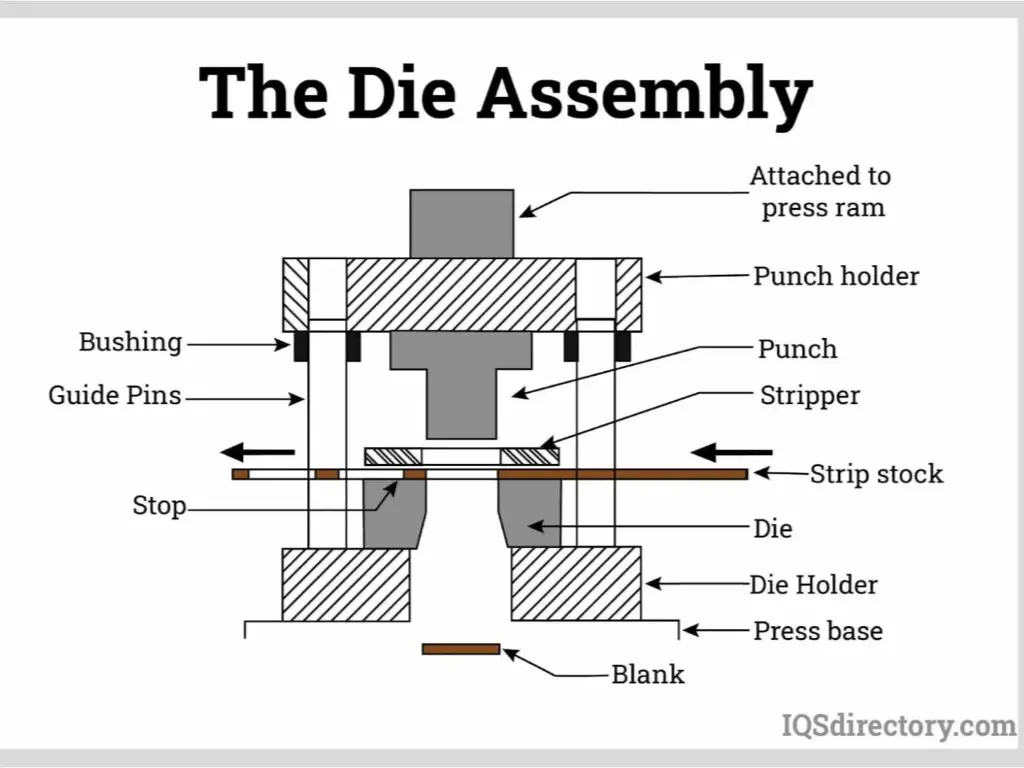

A stamping die is not a solid block but a complicated assembly of precision machined parts, each having a particular purpose. The accuracy and the way these components fit and interact determine the performance, accuracy, and life of the die. These are the main elements that are necessary to comprehend the tool in general.

Source: IQSdirectory.com

- Die Set: This is the basis of the whole tool. It is a matched pair of plates, the upper die shoe, which is mounted to the press slide (ram), and the lower shoe, which is mounted to the press bed or bolster. The die set keeps all other parts in the right position.

- Guide Pins and Bushings: These are the main alignment system of the die. One shoe (usually the lower) has hardened steel guide pins that slide into precision-ground bushings on the other shoe. This system keeps the upper and lower halves of the die perfectly aligned during the press stroke, which is essential to avoiding damage and producing tight part tolerances.

- Punch: The male part is the punch that does the forming or cutting. It is normally attached to the upper shoe. Punches may be plain round to pierce holes or complicated contoured to form features.

- Die Cavity / Die Button / Die Insert: This is the female part into which the punch goes. The shape of the die cavity, along with the punch, determines the shape of the part. One of the most important parameters of a die designer is the clearance, the small space between the punch and the die cavity, which directly influences the quality of a cut edge and the burr amount. In simple holes, this part is commonly a standard, interchangeable die button.

- Stripper Plate: The material tends to adhere to the punch after a punch has pierced or formed the material. The purpose of the stripper plate is to strip the material off the punch as the press starts its upstroke. It may be a rigid plate with a hole to receive the punch or a spring-loaded plate which exerts a downward force on the material during the operation.

- Lifters and Locators: In progressive dies, the material strip has to be lifted off the lower die surface so that it can be fed to the next station. This is done by lifters (or strip lifters). Pins, known as locators or pilots, are inserted into holes already made in the strip to make sure that the strip is positioned accurately at each station.

The Critical Role of High-Wear Custom Mold Parts

Although all parts are significant, a few of them are the ones that take the full force of the operations and are exposed to massive stress, friction, and collision with each press cycle. The most important factors that will determine the part accuracy and life of a die are these high-wear parts, namely the punches, die buttons, guide pins, and bushings. These parts can be worn, chipped, or lose dimensional accuracy due to the constant wear and abrasion of processing materials such as high-strength steel.

The effect of this degradation is instant and drastic on production:

- Loss of Part Quality: Worn cutting edges cause too many burrs and inaccurate features, resulting in part rejection.

- More Downtime: The production has to be stopped to sharpen, service, or replace worn parts.

- Catastrophic Failure: A broken punch or a seized guide pin may result in a die crash, resulting in massive damage and repair bills that may run into thousands.

That is why it is important to source high quality, replaceable parts with excellent durability in any successful stamping operation. U-Need is the expert in precision custom mold parts-cold-forged guide pins, hardened die buttons, and more-designed to withstand the harshest environments and prolong the life of your entire die assembly. Our experience of more than 30 years in the industry is supported by world-class equipment such as Takisawa, GF AgieCharmille, and Sodick to manufacture critical components that are the backbone of our clients stamping tools.

Major Types of Stamping Dies Explained

Stamping dies can be categorized based on their function and construction. The choice of die type is a strategic decision driven by production volume, part complexity, and budget. The three most common types of dies used in modern manufacturing are progressive, transfer, and compound dies.

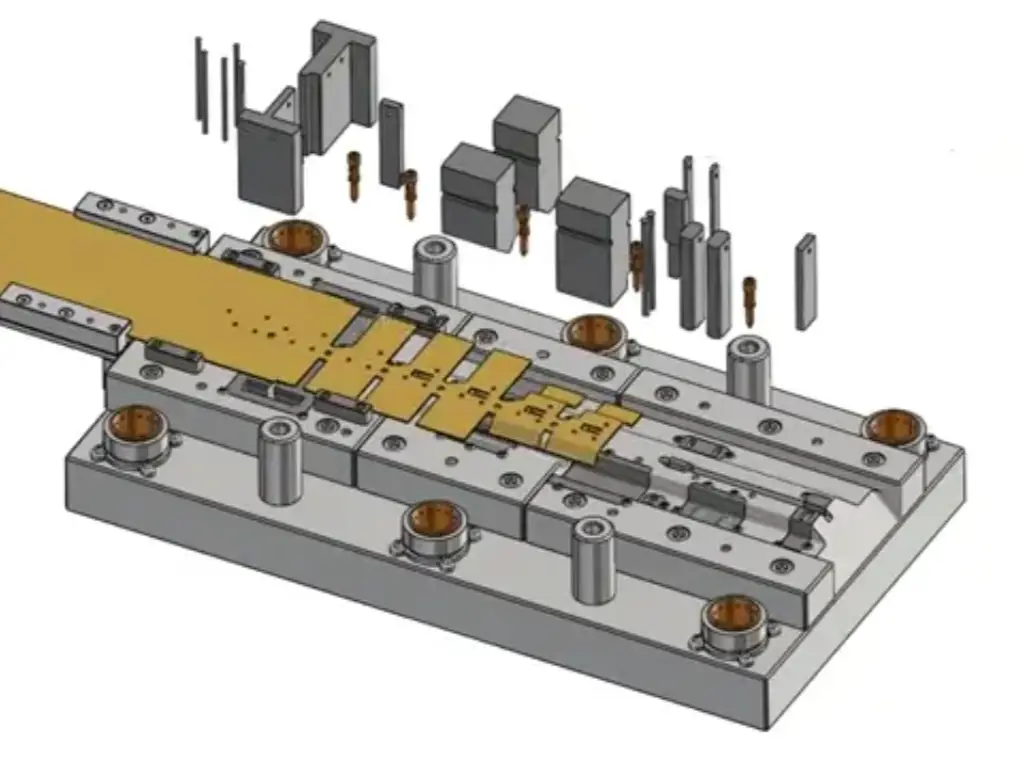

- Progressive Die: A progressive die is the workhorse of high-volume production and is a tool that does a series of forming operations in one tool. A piece of material is passed through the die and on each press stroke a different operation (piercing, bending, coining) is carried out at different next station. This progressive die stamping is a production line that has been reduced to one, small, compact tool.

- Advantages: High efficiency, low labor cost, and high repeatability.

- Disadvantages: More expensive to start, more complicated design, and less flexibility of deep-drawn parts.

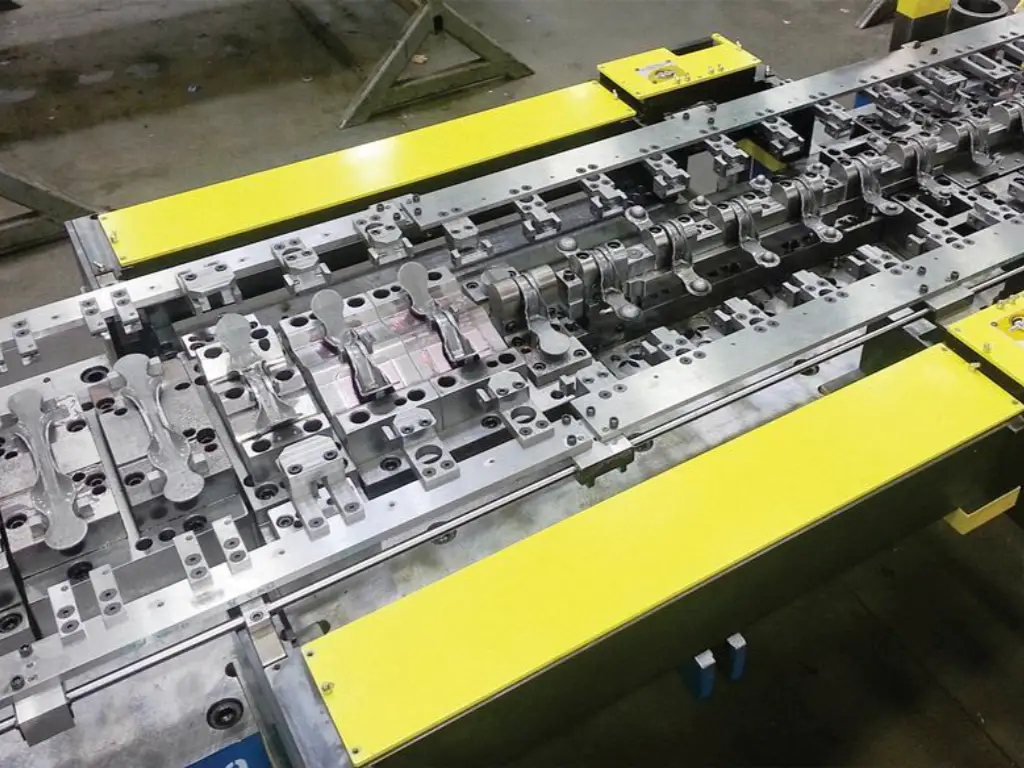

- Transfer Die: Suitable to large and complex parts that need several forming operations, particularly deep-drawn parts such as car body panels. The strip is cut into parts and then a mechanical transfer system moves it between stations. This is often referred to as transfer dies stamping.

- Advantages: It can deal with very complex geometries, large part sizes, and it is possible to have more control over each stage.

- Disadvantages: slower than progressive dies, more expensive to purchase and more floor space is needed.

- Compound Die: A very efficient die which carries out several operations (such as piercing and blanking) in one press stroke. The punch and die are set up to cut the outer shape and the inner holes of a piece at the same time.

- Advantages: High accuracy, burr-free and flat pieces, and fast production.

- Disadvantages: Can only be used on flat sections, and design is not as flexible as progressive dies.

Comparison of Major Die Types

| Feature | Progressive Die | Transfer Die | Compound Die |

| Production Speed | Very High | Medium to High | Low to Medium |

| Initial Tooling Cost | Very High | Very High | Medium |

| Part Complexity | High (Bends, Forms) | Very High (Large, Deep Draws) | Low (Flat Parts) |

| Suitable Volume | High to Very High | Medium to High | Low to High |

| Material Efficiency | Medium (Carrier Strip Scrap) | High | High |

| Typical Applications | Connectors, Brackets, Terminals | Automotive Panels, Cookware | Washers, Gaskets, Shims |

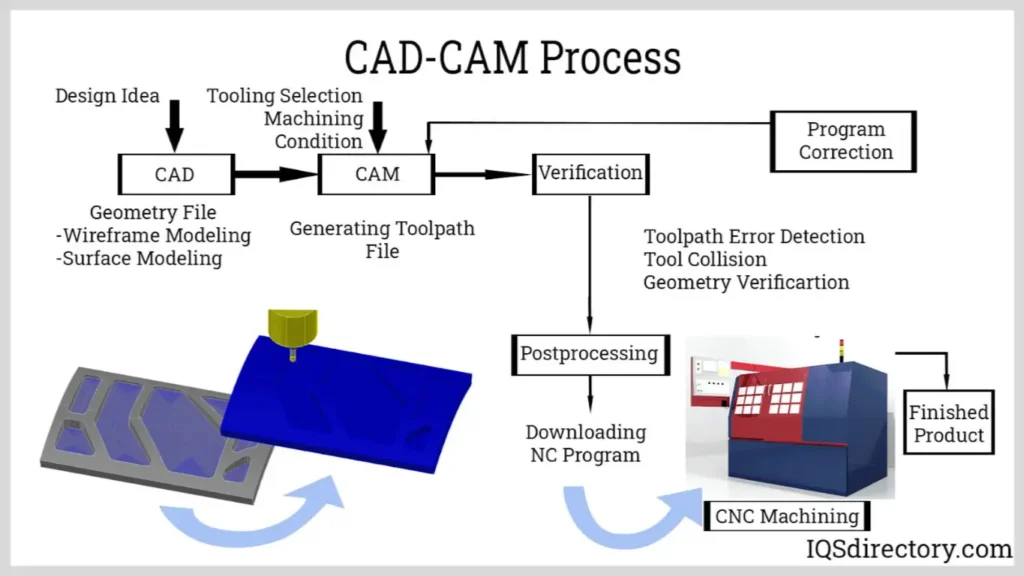

From CAD File to Finished Tool: The Manufacturing Process

The journey from a digital blueprint to a physical stamping die is a testament to the synergy of cutting-edge technology and human expertise. This process is a delicate ballet of machines and minds, where each step builds upon the last to achieve a single goal: uncompromising precision.

Source: IQSdirectory.com

- CAD/CAE Simulation: The process begins in the digital realm, where engineers design the die using advanced software. Finite Element Analysis (FEA) simulations are run to predict material flow and potential forming issues before a single piece of steel is cut.

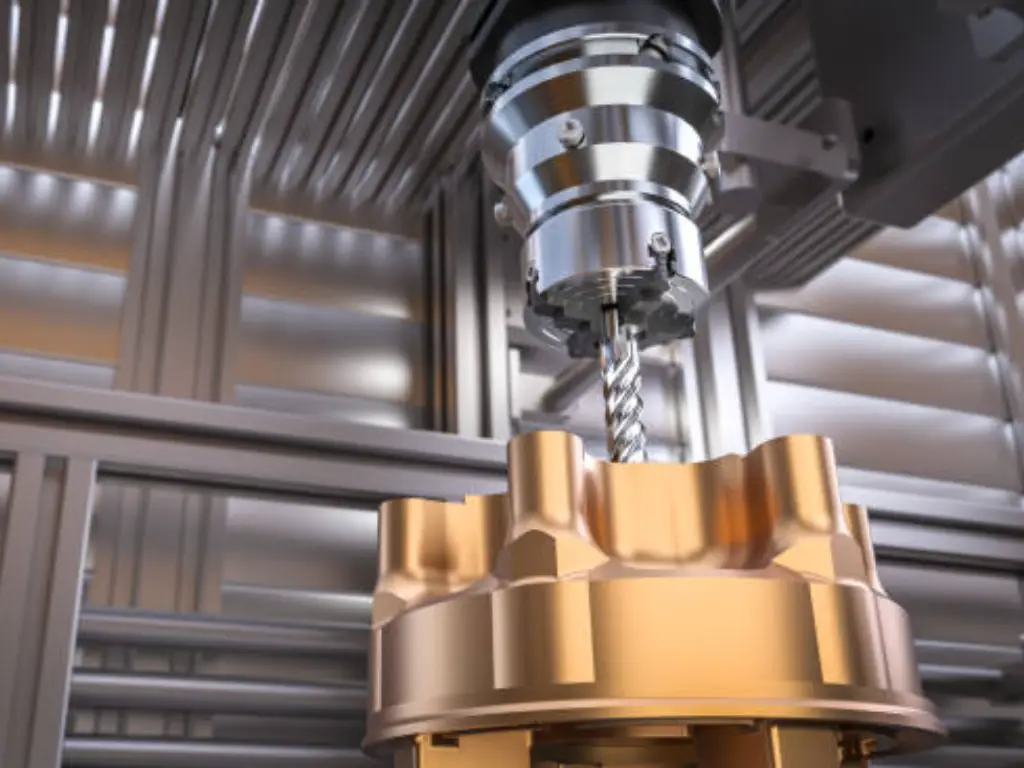

- CNC Machining: The rough shaping of the die components is performed on Computer Numerical Control (CNC) milling machines. These machines follow the digital model to carve out the general forms with high accuracy.

- Wire EDM & Ram EDM: For the fine details and complex geometries, Electrical Discharge Machining (EDM) is used. Wire EDM, in particular, is like a surgical scalpel for metal, using an electrically charged wire to precisely cut intricate shapes and clearances with sub-micron precision.

- Heat Treatment: Once machined, the die components are hardened through a controlled heating and cooling process. This step is critical for enhancing the tool’s strength and wear resistance, giving it the durability to withstand millions of cycles.

- Grinding & Polishing: Precision grinding machines and skilled technicians refine the surfaces of the die components. A mirror-like finish (Ra < 0.1 μm) on the die surfaces is often required, particularly for drawing or cosmetic parts, to ensure smooth material flow and an impeccable final product.

- Assembly & Debugging: The finished components are meticulously assembled. The die is then tested in a press, and any necessary adjustments are made to ensure it functions as designed, a process known as debugging.

Key Factors in Stamping Die Design

The quality, reliability, and cost-effectiveness of a stamping operation are determined long before the die is built. They are forged in the design phase. A well-designed die runs efficiently, produces consistent parts, and has a long service life. Several key factors are paramount in this process.

- Design for Manufacturability (DFM): DFM is a collaborative process between the part designer and the die designer. The goal is to optimize the part’s design to make it easier and more economical to manufacture via stamping. This involves considerations like:

- Bend Radii: Specifying generous bend radii to prevent cracking.

- Hole Placement: Ensuring holes are a safe distance from edges and other features to avoid distortion.

- Feature Orientation: Aligning bends and features to minimize complex operations and reduce die cost.

- Material Selection (Tool Steel & Carbide): The choice of material for the die’s cutting and forming components is critical to its lifespan. The decision is a trade-off between wear resistance, toughness, and cost.

- A2 Tool Steel: A good general-purpose tool steel with a balance of wear resistance and toughness.

- D2 Tool Steel: Higher wear resistance than A2 but less tough, making it more prone to chipping under heavy impact.

- M2 Tool Steel: A high-speed steel that maintains its hardness at elevated temperatures, suitable for high-speed applications.

- Carbide: Extremely high wear resistance but brittle and expensive. Used for very high-volume production or for stamping abrasive materials.

- Tolerance Control and Clearances: A stamping die is a system of controlled tolerances. The precision of the final part is a direct result of the precision built into the die components. The clearance between the cutting punch and the die button, for example, is typically a percentage of the material thickness and must be controlled with extreme accuracy. A clearance that is too tight causes excessive wear and secondary shear on the part edge; a clearance that is too large creates a large, undesirable burr. This is why the ability to manufacture die components to tolerances as tight as ±0.001mm, a specialty of U-Need, is so vital.

- Simulation & Finite Element Analysis (FEA): Modern die design relies heavily on simulation software. FEA allows designers to simulate the entire stamping process digitally before cutting the first piece of steel. This software can predict:

- Material Flow: How the sheet metal will stretch and compress as it is formed.

- Potential Defects: It can identify risks of wrinkling, cracking, or excessive thinning.

- Springback: It predicts how the material will elastically spring back after forming, allowing designers to compensate by “over-bending” the part in the die.

- This simulation saves enormous amounts of time and money by eliminating the traditional, costly trial-and-error process on the shop floor.

Choosing the Right Die for Your Project

Selecting the appropriate type of stamping die is a critical business decision that directly impacts project timelines, part costs, and overall profitability. The choice should be based on a careful analysis of three primary factors: production volume, part complexity, and budget. This decision-making process is at the heart of any successful custom metal stamping project.

- Production Volume

The most important driver is the expected lifetime volume of the part.

- Low Volume (e.g., < 10,000 parts per year): In the case of prototypes or low-volume production, the cost of progressive or transfer dies is prohibitive. Less complex, lower cost tooling such as single-station (or line) dies are the most rational option.

- MediumVolume (e.g., 10,000 – 250,000 parts per year): This volume tends to offer a decision. A compound die can be appropriate on simpler parts, and a simpler progressive die can be a good investment in case the part geometry demands it.

- High Volume (e.g., > 250,000 parts per year): In high annual volumes, the low piece-part price that can be realized with automation is the most important factor. The ultimate solution is progressive and transfer dies because their high initial cost of tooling can be quickly recovered with millions of parts.

- Part Complexity and Size

The die type is strongly limited by the geometry and size of the part.

- Part Size: Large parts, e.g. an automotive door panel, are physically too large to be manufactured in a progressive die and are good candidates to be manufactured in a transfer die. Progressive dies are ideal in small, complex electronic connectors.

- Part Geometry:

- Does the part have cut features only and is it flat? The most accurate will be a compound die.

- Is the part multiple bends, forms or drawn features? These operations require a progressive die to carry them out one after the other.

- Is the part very deeply drawn (depth is larger than diameter) or does it have features on all sides? These complex operations are possible with a transfer die.

- Budget and Return on Investment (ROI)

The analysis should not only be limited to the initial cost of tooling but also the Total Cost of Ownership (TCO).

- Initial Cost vs. Piece-Part Price: A progressive die can cost 100,000, whereas a set of lines dies to make the same part can cost 20,000. The automated progressive die may, however, cost the part at 0.10 and the labor intensive line dies may cost the piece part at 1.50.

- Breakeven Point: The point at which the more costly tool is more profitable can be calculated by a simple calculation. The company will have a much lower cost per piece by investing more upfront, resulting in a much higher return on investment over the life of the project. This TCO analysis is essential to a good financial decision.

Maximizing Die Lifespan and Reducing Costs

A stamping die is a significant capital investment and preserving that investment is essential to long-term profitability. The secret to getting the most out of its life and the lowest possible TCO is a strategic approach to maintenance, which is aimed at repair and component replacement instead of premature full-tool replacement.

A die is a war against wear. Each press stroke is a step towards cutting edge and forming surface degradation. The first line of defense is a thorough maintenance program, which involves cleaning, inspection, and sharpening. Nevertheless, despite the most careful care, the high-wear components will sooner or later come to the end of their service life.

This is the most important decision point where most companies commit a very expensive mistake. Once the quality of the parts is compromised by the wear of the components, the thought of replacing the whole tool, which may cost tens or even hundreds of thousands of dollars, may appear to be the only solution. It is not.

Repair vs. Full Replacement: A Strategic Approach to Cost Reduction

A much smarter and more economical approach is to consider the die as a modular system. Rather than replacing the whole tool, a strategic repair program is aimed at replacing only the high-wear components that have worn out. The large, costly die set and most of the custom-machined blocks have an almost unlimited life. Performance is determined by the small consumable parts. Replacing them allows you to bring the die back to its original operating standard at a small fraction of the cost of a new build.

This is where U-Need comes in with a lot of value. We are a committed manufacturer of custom mold parts and can provide core pins to your injection molds, as well as, the most important parts of your hardware stamping dies. Approximately 60-70 percent of our business is concentrated on these critical components, which allows you to greatly prolong the life cycle of your tool and reduce the cost of operations.

We do not merely provide replacement, we provide improvement.

- Unparalleled Accuracy to Perfect Integration: Our process is founded on precision with more than 30 years of industry experience and a 99.3 percent qualification rate. Our capability to produce tolerances as tight as +/- 0.001mm, which is way beyond industry standards, means that our replacement parts will fit perfectly into your existing dies, and will perform as they did originally without the need to make long-winded and expensive adjustments.

- Extended Life Performance Upgrades: We are not limited by the cost considerations of the original equipment manufacturer. This enables us to provide performance upgrades. We can make replacement parts last 30 percent or more longer than the original parts by suggesting superior materials (e.g., PEEK rather than ordinary plastic, or a better grade of D2 tool steel rather than A2) or by using special surface treatments (we offer 20+ different treatments) such as PVD or chemical nickel plating.

- Responsive Service to Minimize Downtime: We know that downtime is lost revenue. You may require a single replacement component (MOQ of 1) to test a trial run or a complete set of wear parts to your production line, our team of 20+ engineers is at your service. We provide 24-hour quotation service and 1-year warranty on all parts, which is a risk-free route to reduced maintenance costs and maximized uptime. We also engineer special parts to fit special equipment, so you can be sure you will have the non-standard component you require.

With a proactive maintenance and precision component replacement strategy, you will turn your stamping dies into long-term, sustainable production systems instead of depreciating assets.