The pillars of success in the world of high-volume metal part manufacturing are precision, speed, and cost-effectiveness. As a foundational type of metal stamping, progressive die stamping is one of the most powerful metal forming technologies in the world today, with billions of complex components being produced annually to drive our automotive, electronics, medical industries, and consumer goods sectors. To the engineers, procurement managers, and product designers, a thorough knowledge of this process is not only advantageous, but it is also critical to the successful introduction of a product.

This authoritative guide gives a detailed, technical description of progressive die metal stamping. We are going to break down its inner mechanics, contrast it with other traditional processes, and examine its advantages and drawbacks. We will discuss its essential uses, deconstruct the intricacies of cost and tooling management, and give practical Design for Manufacturability (DFM) recommendations. Lastly, we will provide you with the information on how to choose the appropriate manufacturing partner and look into the future of this essential technology. This guide will be your most valuable tool whether you are at the beginning of project assessment or you are trying to streamline an existing production line.

What is Progressive Die Stamping?

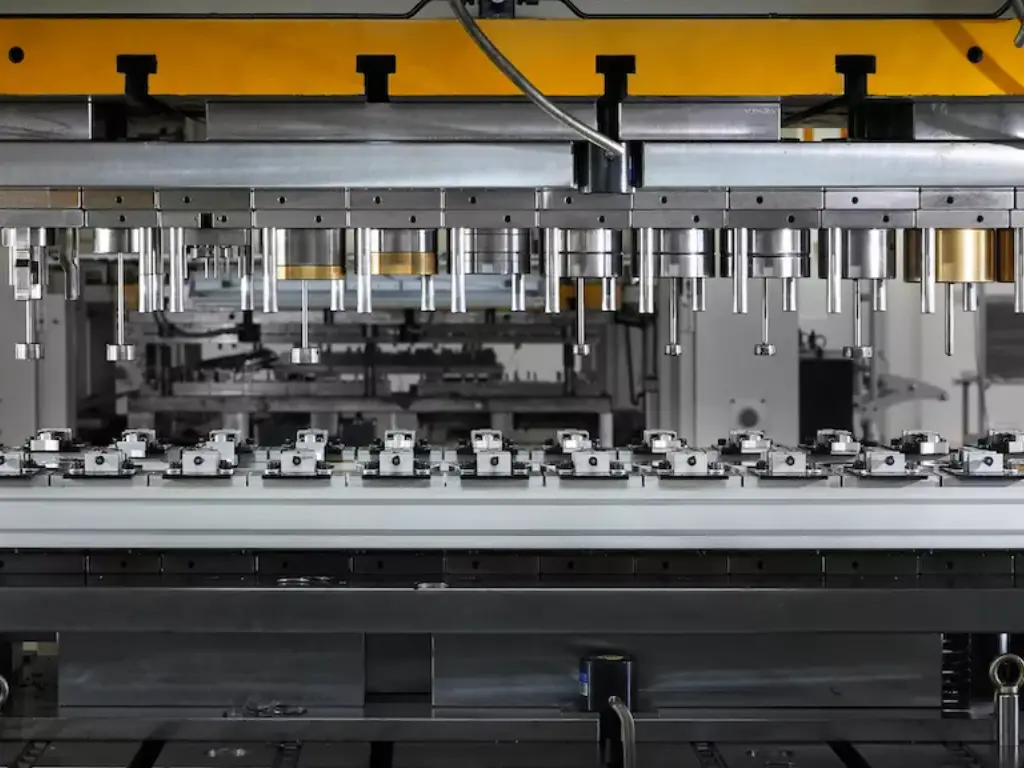

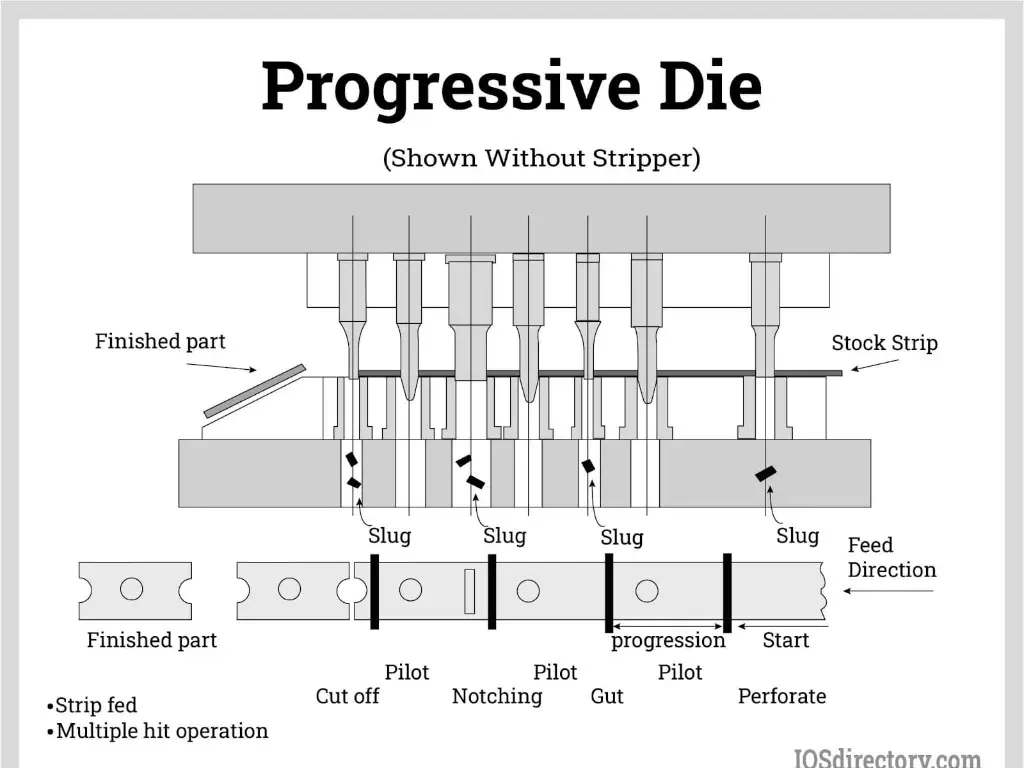

Progressive die stamping is a fast, automated metal forming process that creates complex parts out of a continuous coil of sheet metal. The progressive character of the progressive stamping process is the succession of sequential operations that are carried out on the metal strip as it moves—or progresses—through a sequence of workstations in a single stamping die. The die has a series of stations each of which carries out a different operation, e.g. punching, coining, bending or drawing. The carrier strip, which is a continuous strip of metal, precisely transports the workpiece between stations until the last station, where the finished part is cut out of the strip.

The whole process is contained in a stamping press, which gives the power to cut and shape the material. It is a symphony of mechanical perfection, and is constructed to run continuously, at high volume, with little labor interference after it is installed.

The Step-by-Step Process:

- Material Uncoiling and Feeding: The raw sheet metal, which may be steel, aluminum, copper, or other alloys, is in the form of a large coil. This coil is put on an uncoiler and runs into a straightener to eliminate any coil set (the natural curvature of the material). The straightened strip is then accurately pushed into the progressive die by an automated feeding system at a controlled increment, called the pitch.

- Advancement in the Die: The die itself is a complicated and sturdy device, normally constructed of hardened tool steel, and has several stations. The die closes as the press moves up and down, and a particular operation is performed on each station at the same time.

- Piloting: The punching of pilot holes in the carrier strip is one of the most important early stations. In later stations, cone-shaped pilots in the upper half of the die are inserted into these holes prior to any forming. This provides a perfect strip alignment on each press stroke, which is essential to tight tolerances.

- Stamping Operations: The strip is passed through a series of stations which may comprise:

- Piercing/Punching: Making holes, slots, or cutouts.

- Bending/Forming: Making angles, flanges or complex shapes.

- Drawing: Shallow cup-like shapes.

- Coining/Embossing: Stamping details such as logos, text or stiffening ribs.

- Trimming: Removal of unnecessary material.

- Part Ejection: The last part is the separation of the completed part with the carrier strip. The finished sections are pushed out of the press, usually onto a conveyor belt to be collected, and the rest of the carrier strip skeleton is cut into small pieces to make efficient scrap collection and recycling.

Since all these operations are performed in one die in one press, progressive die stamping can produce hundreds or even thousands of parts per minute, and is therefore an extremely efficient process of mass production.

(Aanimated video placed here would effectively illustrate the metal strip progressing through the die stations.)

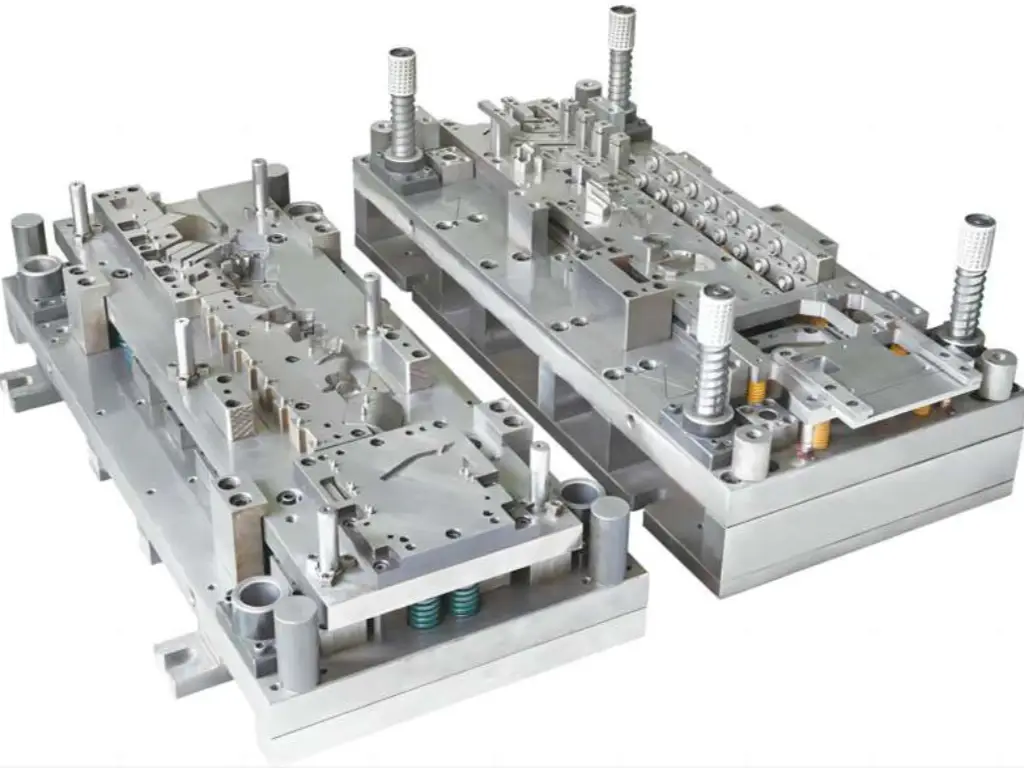

Anatomy of a Progressive Die: Key Components

In order to comprehend the process and its costs, it is important to know the major parts that constitute a progressive die. These components operate under severe conditions, and their quality determines the performance and the life of the tool.

Source: IQSdirectory.com

- Die Set: This is the basis of the tool. It is composed of a heavy upper shoe and lower shoe, usually of cast iron or steel. These shoes are machined to exact specifications to keep all other parts in perfect alignment through guide pins and bushings so that the die closes the same way every time the press is stroked.

- Punches: These are the male parts that do the job of cutting or shaping the material. They are exposed to enormous impact and stress and thus are high-wear components.

- Piercing Punches are applied to make holes.

- Forming Punches are designed to bend, draw, or coin the material into the desired geometry. The accuracy of their work directly reflects on the accuracy of the final part.

- Die Buttons / Matrix: These are the female equivalent of punches, and are usually precision-ground, hardened steel or carbide inserts. When piercing a hole, the punch goes into the die button to cleanly shear the material. Similar to punches, they are high-wear items which need to be replaced periodically.

- Pilots: These are cone-shaped pins, precision-ground, which fit into pilot holes on the carrier strip. They are strictly alignment devices, yet they are essential. Pilots are directly involved in the high repeatability and tight tolerances of the final parts by accurately locating the strip prior to every forming or cutting operation.

- Stripper Plate: The material tends to adhere to the punches as they retract as the press opens following a stroke. The stripper plate is a plate that encompasses the punches and is spring loaded. It grips the strip of material securely throughout the process and then strips it off the punches as they withdraw, so that the strip can move freely to the next workstation.

- Lifters and Guides: These are a set of pins, rails and blocks that guide, lift and support the carrier strip as it passes through the die. They stop the strip buckling or sagging and allow reliable and jam-free feeding between stations.

- Die Inserts / Blocks: The die block is usually made of a single piece of expensive tool steel, but complex or high-wear areas may be made as separate, replaceable Die Inserts. These inserts that hold essential cutting or forming geometry can be produced with high quality materials such as tungsten carbide. This modular design is one of the major cost saving measures; when an area becomes worn out, only the small insert must be replaced, not the whole, huge die block. This targeted replacement philosophy is the core of effective tooling lifecycle management.

Progressive Die vs. Transfer Die vs. Fourslide

Choosing the right stamping process is a critical decision that impacts tooling cost, production speed, and part complexity. Progressive die stamping is not a one-size-fits-all solution. Understanding its advantages in relation to other common methods like transfer die stamping and fourslide (or multi-slide) stamping is key for proper project planning.

| Feature | Progressive Die Stamping | Transfer Die Stamping | Fourslide / Multi-slide Stamping |

| How it Works | Continuous metal strip moves through one multi-station die. | Single parts are moved between separate dies by a transfer system. | Material is shaped by multiple tools moving from different directions. |

| Best Suited For | • High-volume small/medium parts • Terminals, brackets, shields | • Large or deep-drawn parts • Parts needing free access | • Intricate, complex bends • Clips, springs, wire forms |

| Production Rate | Very High | Medium to High | Medium |

| Tooling Investment | High | Very High | Medium to High |

| Material Usage | Good (Carrier strip is scrap) | Fair (Blanks can create waste) | Excellent (Minimal scrap) |

| Setup & Changeover | Long | Very Long | Medium |

In summary, progressive die stamping is the king of speed and efficiency for high-volume production of parts that can be carried on a strip. Transfer die stamping offers greater flexibility for larger or deep-drawn parts that cannot remain attached to a strip, at the cost of higher tooling investment and slower speeds. Fourslide stamping carves its own niche, excelling at producing small, highly complex wire and strip forms that would be difficult or impossible to create in a conventional vertical press.

Key Benefits and Limitations for Your Project

Making an informed decision requires a balanced view of technology. While progressive die stamping is incredibly powerful, it’s essential to weigh its advantages against its constraints in the context of your specific project requirements.

Benefits of Progressive Die Stamping

- Rapid Production Rate: This is the greatest strength. Production rates are very high with automated feeding and several operations being performed with each press stroke. This renders the process well suited to large orders (usually tens of thousands to millions of parts) with short lead times.

- Low Part Cost at Volume: The cost of the tooling is high, but the cost of the part is extremely low once the production is started. The economies of scale are remarkable due to the high speed, automated nature, and the little labor required to operate. It is usually the most economical metal forming process when large quantities of production are involved.

- Good Repeatability and Consistency: The fixed geometry of the die and the accuracy of the feeding system controls the process. After the die is qualified, all the parts made will be virtually the same as the previous one. This provides close tolerances and repeatable quality across the entire production run, which is essential in applications where interchangeability of parts is paramount such as in automotive and electronics.

- Less Scrap Material: A properly designed progressive die will have a well thought out carrier strip layout (nesting) that will allow the most parts to be produced out of a given piece of material. This effective use of materials reduces wastage as compared to other processes, which helps in reducing the total cost of parts.

Limitations of Progressive Die Stamping

- High Initial Tooling Cost: The first disadvantage is that it is very costly to design and construct a progressive die. They are precision-engineered tools, complex in nature, and may cost tens of thousands to hundreds of thousands of dollars, depending on the complexity of the part, its size, and the desired life. This is very expensive and therefore not suitable for prototypes or small production runs.

- Inappropriate to Low Volumes: The tooling cost is high, so a large production volume is required to justify the investment and produce a competitive part price. Before deciding to use this technology, the break-even point should be well calculated.

- Design Constraints: The part should be designed in such a way that it can be transported between the stations on the carrier strip until the last operation. This may at times place restrictions on the geometry of the part. Moreover, because all operations are done in one press direction (vertically), features that must be formed in more than one direction cannot be done without complicated in-die mechanisms.

- Tooling Lead Time: The design, construction, and qualification of a new progressive die is a time-consuming process and can take several weeks or months. This lead time should be considered in the total project schedule.

Key Applications Across Top Industries

The efficiency, precision, and cost-effectiveness of progressive die stamping have made it an indispensable technology across a wide range of industries. Its applications are ubiquitous, found in many of the products we use daily. Understanding these applications provides a real-world context for the value of the process.

Automotive

One of the biggest consumers of progressive stamped parts is the automotive industry where large volumes, tight tolerances, and reliability are not negotiable.

- Connectors and Terminals: A vehicle has dozens, or even hundreds, of precision terminals and connectors in every wiring harness to route power and data. The only feasible way of making these at the necessary scale and cost is progressive stamping.

- Brackets and Clips: Small sensor mounting brackets in the engine bay, interior trim clips and seatbelt retractor components are all stamped parts used to fasten and support the vehicle.

- ECU and Module Housings: Progressive stamping is commonly used to make the protective metal enclosures of Electronic Control Units (ECUs) and other electronic modules, to offer EMI/RFI shielding and physical protection.

- Heat Shields: Thin, stamped aluminum or steel heat shields that shield sensitive parts against exhaust heat are formed in huge quantities.

Electronics and Telecommunications

The electronics industry is a high-paced industry where miniaturization and precision are important. Progressive stamping provides the complex, high-precision parts needed in a huge variety of devices.

- EMI/RFI Shielding: Stamped metal cans or shields are custom-designed to isolate sensitive electronic components against electromagnetic and radio-frequency interference, which is a critical need in smartphones, routers, and computers.

- Lead Frames: These are metallic frames that support silicon chips and connect them to the outside pins of an integrated circuit package. They need microscopic accuracy, which is ideally suited to progressive stamping.

- Contacts and Connectors: USB connector shells, internal battery contacts, board-to-board connectors, and many more are made with stamped parts and are essential to making reliable electrical connections.

- Heat Sinks: Small stamped aluminum heat sinks are found in many devices to cool processors and power components.

Medical Devices

The health sector requires utmost accuracy, hygiene, and traceability of materials. Progressive stamping is applied to manufacture parts of both disposable and durable surgical equipment.

- Surgical Instrument Parts: Most surgical stapler parts, cutting instruments, and other handheld surgical instruments are stamped out of medical grade stainless steel.

- Implantable Device Casing: The protective housings of devices such as pacemakers and defibrillators need hermetically sealed, biocompatible metal housings, which may be produced by deep-draw or progressive stamping.

- Diagnostic Equipment Parts: Diagnostic equipment parts such as components of diagnostic machines, fluidic control systems, and testing equipment are frequently manufactured through stamping due to their repeatability and cost-effectiveness.

Aerospace and Defense

Although aerospace volumes are generally smaller than automotive, progressive stamping is also applied to standardized, high-volume parts where precision and material integrity are critical.

- Fasteners, Shims, and Washers: Standard and custom fasteners, precision shims to compensate tolerances, and special washers are stamped in a wide range of types.

- Small Structural Components: Small brackets, fittings, and other non-critical structural components are frequently stamped out of high-strength aluminum or steel alloys.

Understanding and Managing Progressive Die Costs

For any project manager or engineer, controlling costs is a primary objective. With progressive stamping, the cost structure is heavily weighted towards the initial tooling investment. A comprehensive understanding of how to manage both the upfront and long-term costs is crucial for maximizing the return on investment (ROI) of your project.

Initial Investment vs. Long-Term Savings

The economic model of progressive stamping is a classic trade-off. You accept a high initial cost to “buy” an extremely low price per piece for the duration of a long production run.

- Breaking Down Tooling Costs: The initial die cost is a composite of several factors:

- Design & Engineering: Hours spent by skilled tool designers to model the part, plan the strip layout, and design the die stations.

- Raw Materials: The cost of high-quality tool steels (like D2 or carbide for high-wear areas) and the die set base.

- Precision Machining: The extensive use of CNC milling, wire EDM, sinker EDM, and precision grinding to create the die components to micron-level tolerances.

- Assembly & Tryout: The labor-intensive process of assembling the die, testing it, and making micro-adjustments to ensure it produces parts that meet all specifications.

- Calculating the Break-Even Point: The decision to invest in a progressive die hinges on the break-even point—the volume at which the total cost of progressive stamping becomes lower than an alternative process (like laser cutting + forming). A simplified calculation is:

- Break-Even Volume = (Progressive Tooling Cost) / (Cost per Piece (Alternative) – Cost per Piece (Progressive))

- This calculation highlights why volumes in the tens or hundreds of thousands are typically required to justify the investment.

The Hidden Factor: Tooling Maintenance & Lifecycle

The actual ROI of a progressive die is not only the cost of the die, but the productive life of the die. Another cost that is not usually considered in progressive stamping is the long term maintenance of tools and downtime. Dies are precision tools that are exposed to enormous stress due to millions of high-impact cycles. Important parts such as punches, pilots, and die inserts are bound to wear out, chip, or break. The conventional method may include expensive emergency repairs or in worst case scenario, replacing the entire expensive die set.

But a more economical approach is proactive, lifecycle-oriented maintenance with high quality, custom replacement parts. It is not just repair but a plan to get the most out of the asset.

Increase Die Life and Reduce Costs through Custom Mold Parts

This is where the production of specialized components is essential. U-Need specializes in precision, custom mold parts, specifically progressive dies, injection molds and other industrial tooling. The whole business model is designed to respond to the long-term operational costs that our clients have. You can greatly increase the lifecycle of your initial investment and cut maintenance costs by replacing only the worn-out, critical components, not the entire die.

We have developed our expertise in the precision machining industry over 30+ years and we have the ability to cover the 60-70% of key wear parts that are the core of any tool, such as cold heading, stamping and injection molds. When a punch of standard tool steel becomes worn out, we can re-engineer and produce a replacement of a higher grade of carbide, which may have twice or even three times the life. In the event of a complex forming insert failure, our team of engineers (with an average of over 15 years experience) can replicate it to a precision of up to +/- 0.001mm, and in many cases even better than the original.

We use the best equipment in the world such as PG optical curve grinders to produce ultra-precise profiles on punches and inserts, tolerances and surface finishes that cannot be achieved in a standard machine shop. This enables us to manufacture parts for the most challenging applications, such as semiconductor molds with 0.02mm internal corner radii. We don t simply replace parts, we upgrade them by concentrating on high-quality materials, state-of-the-art manufacturing techniques such as mirror EDM and multi-process machining, and a thorough knowledge of tooling wear patterns. This proactive strategy will help your production lines stay in operation with minimal downtime and will turn your tooling into a long-term high-performance asset instead of a consumable cost.

Critical Design (DFM) Considerations for Stamping

Effective part design is a collaboration between the product designer and the manufacturing engineer. Applying Design for Manufacturability (DFM) principles at the earliest stages is the single most effective way to reduce costs, improve quality, and ensure a smooth production launch.

Material Selection

The selection of the material influences the cost, formability and the final part performance.

- Formability: Low-carbon steel, aluminum, and copper alloys are highly ductile and can be easily formed into complex bends and draws. Stainless steels and high-strength steels (HSS) are less tolerant and might need bigger bend radii and stronger tooling.

- Cost: Raw material is a major cost driver of part. Always ask yourself whether a more costly material is really needed in the functional requirements of the application.

- Hardness and Wear: Hardness of the material will influence the wear rate of the die. Stamping abrasive or very hard materials will necessitate the die being constructed using more costly, wear resistant tool steels such as carbide.

Tolerances

Cost is directly and exponentially affected by tolerance.

- Only Specify What is Required: The narrower the tolerance, the more costly the die will be to construct and support. A tolerance of +/- 0.1mm is normal and fairly easy to attain. To make that ±0.01mm, much more accurate manufacturing and quality control is needed.

- Micron-Level Precision: Tolerances as fine as +/- 0.001mm are possible, as shown by specialty shops such as U-Need, but should be used only on the most important functional characteristics. One of the most common and expensive design mistakes is over-tolerancing a part.

Hole and Slot Features

To avoid breaking punches and to guarantee part quality, follow these rules of thumb.

- Hole Diameter vs. Material Thickness: The thickness of a punched hole must be at least as large as the diameter of the hole. In the case of tougher materials, this ratio must be even bigger (e.g., 2:1). Breaking this may result in over-wearing punches and breakage.

- Distance Between Features: The distance between the edge of a hole and the edge of the part, or between two holes, must be at least two times the thickness of the material to avoid distortion and preserve the strength of the material.

Bends and Shapes

The process of making bends must take into account material properties.

- Minimum Bend Radii: All materials have a minimum inside bend radius below which they will crack. This radius is usually given as a multiple of the thickness of the material (e.g. 1T, 2T). See material datasheets to find specific recommendations. Always make the largest radius you can.

- Springback: In the case of a material that is bent, it will tend to spring back a little once the forming pressure is removed. This is called springback and has to be allowed in the die by over-bending the part. This can be anticipated and taken into consideration by experienced tool designers.

- Bending Orientation: Bending along the grain direction of the material may cause the material to crack. Bends should always be oriented at right angles to the grain.

Carrier Strip Design

Although the designer is concerned with the last part, the carrier strip is equally significant in terms of manufacturability. The strip should be stiff enough to support the part to all stations without distortion and give safe places to put pilot holes.

Choosing the Right Stamping Partner

The success of your project depends heavily on the capabilities and philosophy of your manufacturing partner. Choosing a supplier should go far beyond simply comparing price quotes. You are selecting a partner who will be an extension of your team, responsible for managing a critical asset—your tooling.

Here is a checklist of what to look for:

- Engineering and DFM Expertise

A low-cost quote is worthless if the supplier cannot provide upfront engineering support. A great partner will act as a consultant.

- What to Ask: “Can you provide a DFM report on our design? What suggestions do you have to reduce cost or improve quality?”

- What to Look For: Look for a partner with a dedicated engineering team that can offer concrete suggestions. A partner like U-Need, with a 20+ engineer team averaging 15 years of experience, has the deep expertise to analyze a part and recommend changes that save money over the life of the project.

- Manufacturing and Quality Systems

The quality of the parts is a direct reflection of the quality of the partner’s equipment and processes.

- What to Ask: “Can we see your equipment list? What are your quality certifications? What is your QC process?”

- What to Look For: A top-tier supplier will have invested in world-class equipment (GF AgieCharmille, Sodick, Takisawa). They will be ISO 9001:2015 certified and have a multi-stage QC process, including incoming material inspection, in-process checks, and final full-dimensional inspection using advanced equipment like CMMs and 2.5D projectors. A claimed pass rate of 99.3% or higher is a strong indicator of robust process control.

- Tooling Lifecycle Management and Support

This is what makes a difference between a supplier and a partner. Their attitude towards tooling maintenance demonstrates their interest in your long-term success in operation.

What to Ask: What is your tooling maintenance and repair procedure? Where do you get your replacement parts? How fast do you respond to a line-down emergency?”

What to Look For: The better response to this question is a proactive approach. In vetting a partner, inquire on their supply chain of critical components. The capability of fast ordering of non-standard, long-lasting parts is essential to reduce downtime. This is not only in the mold but also in the stamping equipment.

We are the strategic partner of the best manufacturers at U-Need. We also design custom equipment components along with mold parts so that all of your production line, not just the tooling, can be maintained to perform at its best and last as long as possible. We can support a MOQ of 1 piece and can deliver urgent orders in 3-5 days, which is the flexibility and responsiveness required to avoid long periods of downtime. A stamping partner with an in-built relationship with a specialist such as us is showing a profound interest in ensuring that your uptime is maximized and your total investment is safeguarded.

Future Trends in Progressive Die Stamping

While progressive die stamping is a mature technology, it continues to evolve. Innovation is driven by the demand for more complex parts, the adoption of new materials, and the integration of digital technologies.

Simulation and Digital Twins

Advanced Finite Element Analysis (FEA) software allows tool designers to simulate the entire stamping process digitally. They can predict material flow, identify potential stress points, anticipate springback, and optimize the strip layout before a single piece of steel is cut. This “digital twin” of the die drastically reduces the costly and time-consuming trial-and-error phase of tool development.

IIoT and In-Die Sensing

The Industrial Internet of Things (IIoT) is transforming tooling maintenance from a reactive to a predictive discipline. By embedding sensors directly into the die, it’s possible to monitor critical parameters like pressure, temperature, and vibration in real-time. This data can be analyzed to predict when a component is beginning to wear or fail, allowing maintenance to be scheduled proactively before it causes a line-down situation.

Advanced Materials

The push for lightweighting in the automotive industry and higher performance in electronics is driving the adoption of new materials. Stamping advanced high-strength steels (AHSS), aluminum alloys, and even titanium presents new challenges. This requires innovations in die materials, coatings, and lubricants, as well as new press technologies, to successfully form these less-forgiving materials.

Hybrid Manufacturing Processes

The future may lie in combining processes within a single die. This could include integrating in-die laser welding to join two parts, in-die tapping to create threaded holes, or the automated insertion of components like nuts or studs. These hybrid processes can eliminate secondary operations, reduce part handling, and lower overall costs.

Progressive die stamping remains a cornerstone of modern manufacturing. Its fundamental principles of speed, precision, and efficiency are timeless. By understanding its mechanics, managing its costs strategically, designing for manufacturability, and choosing partners who are invested in your long-term success, you can fully leverage the power of this remarkable technology.