Die stamping, a form of custom metal stamping, is a pillar of modern manufacturing, a fast, accurate process that makes an incredible amount of metal parts we use in our daily lives.Whether it is the complex connectors within our smartphones or the structural body panels of our cars, the effects of die stamping are everywhere. To an engineer, procurement manager, and designer, a thorough knowledge of this technology is not only advantageous, but it is a necessity in the development of cost-effective, reliable, and scalable products.

This detailed guide will take a closer look at the fundamentals of die stamping, its different processes, the important operations that are involved, and the complex design of the stamping die itself. We will look at some of the most important industrial applications, walk you through the process of selecting materials, and give a clear comparison to other manufacturing processes. We shall also examine the lifecycle of stamping tools and present some ideas on how to get the most out of them and extend their life, and lastly we shall examine the future of this dynamic industry.

What is Die Stamping? An Overview

Die stamping is a cold-forming manufacturing process at its core, which is used to form or cut flat sheet metal into a desired geometry. It is done by sandwiching a sheet of metal between two halves of a special tool known as a die. Then a stamping press is used to exert a tremendous amount of force, which plastically deforms or shears the material to the shape of the die. Although commonly interchangeable with the more general term sheet metal stamping, die stamping in particular focuses on the die as the forming tool. It is the core of the operation, with carefully designed metal stamping dies determining the size, features and part accuracy of the final component. The entire metal stamping process may be divided into three main components:

- The Stamping Press: The machine which supplies the force (tonnage) to close the die. Presses may be mechanical or hydraulic, and range in size, from small bench-mounted presses to huge machines that fill a room.

- The Stamping Die: The special tool, usually of hardened tool steel, which has the cavity or shape into which the sheet metal is formed. It is made up of an upper and lower part which fit together. The Workpiece: The raw material, which can be a metal workpiece in the form of a sheet, coil, or pre-cut blank. Common materials include steel, aluminum, copper, and stainless steel.

The basic concept of die stamping is based on plastic deformation. When the press force is greater than the elastic limit of the metal, the metal permanently assumes the shape of the die. When the force is focused on a sharp edge, it will be greater than the shear strength of the material, and a cutting or blanking operation will occur. It is this capability to cut and shape in a single stroke, a high-velocity operation, that makes die stamping an extremely efficient process for mass

Key Die Stamping Processes and Types

The term “die stamping” encompasses several distinct types of dies and processes, each optimized for different part complexities, production volumes, and cost considerations. Selecting the best die stamping process is a critical decision that impacts project cost, lead time, and part quality. The three most prominent types are progressive, transfer, and compound die stamping.

Progressive Die Stamping

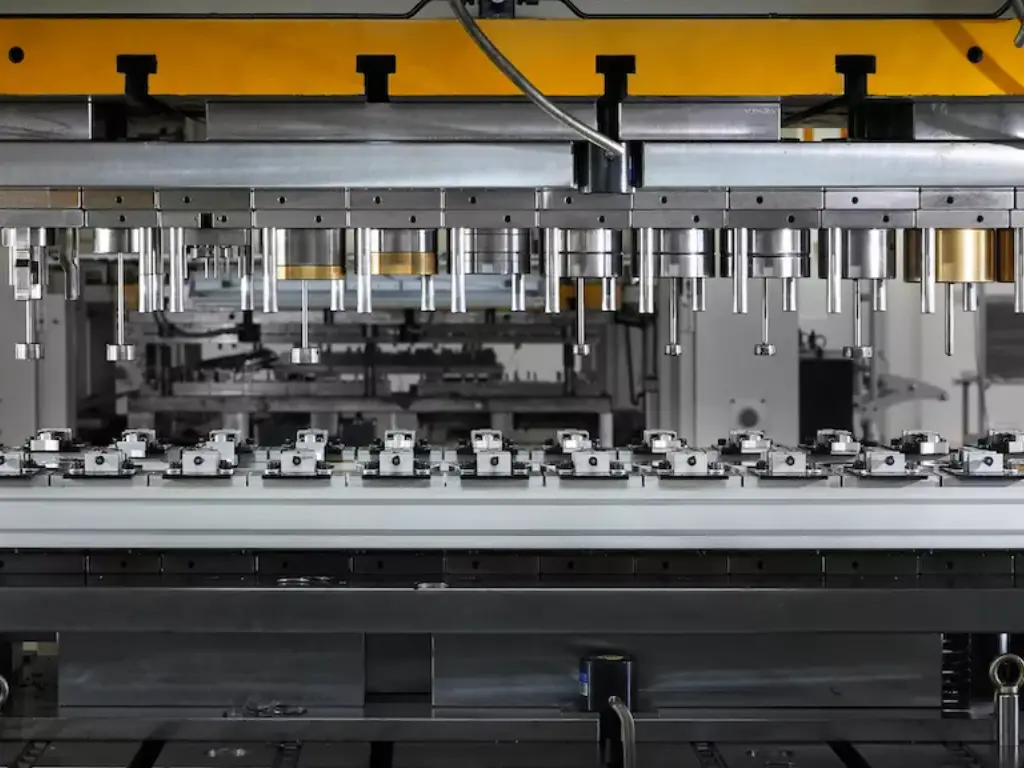

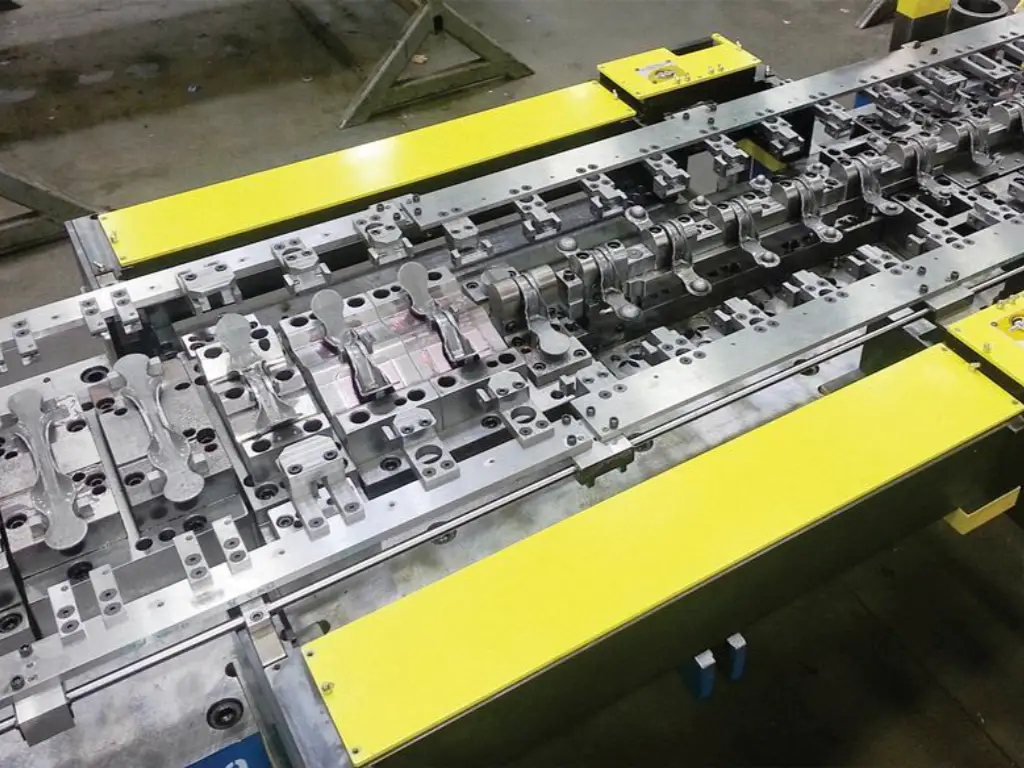

The ultimate high-volume, high-efficiency metal forming is progressive die stamping. During this process, a metal strip is fed from a coil through the press and into a die with different stations. As the press cycles, the material moves or advances a specific distance through the die with every press cycle. Each station has a particular operation (punching, coining, or bending) carried out at the same time.

The part is held on the carrier strip throughout its passage through the die so that it is perfectly aligned at each step. The finished portion is then cut off the strip in the last station. This is an automated, continuous process that can produce complex parts at extremely high rates of speed, sometimes hundreds or even thousands of parts per minute.

- Working Principle: Continuous feeding of material, several operations per press stroke, part stays on carrier strip until the last operation.

- Advantages:

- Extreme Speed: Suitable when production volumes are very high (hundreds of thousands to millions of parts).

- Low Per-Part Cost: After the tool is constructed, the labor and operational cost per part is very low.

- High Repeatability: Achieves very consistent and accurate parts because the tooling is fixed.

- Complex Geometries: Able to produce complex parts through the integration of numerous operations into a single tool.

- Disadvantages:

- High Tooling Cost: Progressive dies are complicated and costly to design and construct.

- Long Tooling Lead Time: The process of designing and making the die may take weeks or months.

- Material Waste: The carrier strip that is required in feeding becomes scrap material.

Transfer Die Stamping

Transfer die stamping is similar to progressive stamping because it uses a single press with multiple stations to carry out a series of operations. But the essential difference is this: once the part has been cut out of the sheet (blanked) it is no longer attached to a carrier strip. Thereafter, the individual part is transferred by a mechanical transfer system, usually with the use of fingers or grippers, from one operation to the next station within the press. This is accomplished using specialized transfer dies.

This process is especially suitable to larger pieces which are not easily supported on a carrier strip, or to pieces which must be deep drawn and the material must be allowed to flow freely without being confined by a strip.

- Working Principle: The individual part blank is separated, and then transferred mechanically between stations to perform the next operations.

- Advantages:

- Large Parts: Suitable to use on parts that are too large or bulky to fit in a progressive die.

- Flexibility: Enables operations such as deep drawing and enables access to the part in all directions.

- Less Material Waste: No carrier strip is required, which can enhance material usage.

- Disadvantages:

- Reduced Production Speed: The mechanical transfer is slower than the continuous feed of a progressive die.

- Expensive Tooling and Equipment: It needs a complicated transfer system besides the die set.

- Complexity: The coordination between the press and the transfer system introduces an element of complexity to the system.

Compound Die Stamping

A compound die does several cutting actions in a single press stroke at one station.These operations are usually done in a single step, both to form internal features (such as holes) and the external outline (blanking) of the part. Both the internal and external cuts punch and die components are mounted on the same station.

This technique is famous because of its high precision in preserving the positional relationship between features. Since all the cuts are done simultaneously with the material completely constrained, the concentricity and feature-to-edge tolerances can be maintained to a very high level. It is mostly applied in the manufacture of relatively flat components, like washers or gear blanks, where precision in dimensions is of utmost importance.

- Working Principle: Several cutting operations are carried out at one station by one press stroke.

- Advantages:

- Great Dimensional Precision: Better management of feature-to-feature and feature-to-edge tolerances.

- High Repeatability: Makes very flat, consistent parts.

- Less Expensive on Less Complex Parts: Tooling may be simpler than progressive dies in some applications.

- Disadvantages:

- Slower than Progressive Stamping: One part is made per stroke and the process is not continuous.

- Limited Part Complexity: Normally limited to flatter parts and is unable to do major forming operations such as deep drawing.

- Scrap Removal: Ejection of the finished part and the internal slugs may be more complicated.

Comparison of Die Stamping Processes

| Feature | Progressive Die Stamping | Transfer Die Stamping | Compound Die Stamping |

| Ideal Production Volume | Very High (100,000+) | Medium to High (10,000+) | Low to High |

| Per-Part Cost | Very Low | Low to Medium | Low |

| Tooling Cost & Lead Time | Very High | High | Medium to High |

| Production Speed | Very Fast | Medium to Fast | Slow to Medium |

| Maximum Part Size | Small to Medium | Medium to Very Large | Small to Medium |

| Part Complexity | High (Multiple Bends, Forms) | High (Especially Deep Draws) | Low to Medium (Primarily Flat) |

| Dimensional Accuracy | Good to Excellent | Good | Excellent |

| Material Utilization | Moderate (Carrier Strip is scrap) | Good to Excellent | Good |

| Best For | Small, complex parts like connectors, terminals, and brackets in mass production. | Larger parts like automotive body panels, deep-drawn shells, and appliance housings. | Flat parts requiring high precision, such as washers, shims, and gear blanks. |

Core Operations: From Blanking to Drawing

Within each stamping process, a series of fundamental operations are performed to transform the raw sheet metal. These can be broadly categorized into cutting operations and forming operations.

Cutting Operations (Shearing)

These processes entail the use of a force that is so great that it surpasses the shear strength of the material and the material fractures and splits along a specific line.

- Blanking: The process of shearing the whole outer outline of a piece out of a larger sheet. The desired workpiece is the piece that is cut out.

- Piercing (or Punching): The process of making an internal hole or a slot in a part. The scrap (slug) is the material cut out.

- Trimming: A secondary process that is employed to eliminate extra material or burrs on the edge of a formed part to produce the final, accurate dimension.

- Notching: A machining process that takes away material on the edge of a workpiece.

Forming Operations

These operations deform the material beyond its elastic limit without intentionally causing it to fail or fracture.

- Bending: The process of straining material along a straight axis, creating a permanent angle. This is one of the most common forming operations, used to create features like flanges and tabs.

- Drawing: This operation forms a flat blank into a three-dimensional, hollow shape. It is achieved by forcing the material into a die cavity with a punch. Deep drawing refers to cases where the part’s depth is greater than its diameter. This is used to make products like cans, shells, and housings.

- Coining: An intense squeezing operation where the material is forced to flow into the fine details of a die. It applies extremely high pressure to create sharp features, inscriptions, or very smooth surfaces. The manufacturing of currency coins is a prime example.

- Embossing: A process used to create a raised or sunken design in sheet metal. Unlike coining, embossing involves stretching the material and results in minimal change to the material’s thickness.

The Stamping Die: Design, Wear, Longevity and Cost

The stamping die is the heart of the entire manufacturing process. Its design, material, and condition directly dictate the quality of the final part, the efficiency of the production run, and the overall profitability of the operation. A well-designed die can run millions of cycles with minimal intervention, while a poorly constructed one can lead to constant downtime, part defects, and excessive costs.

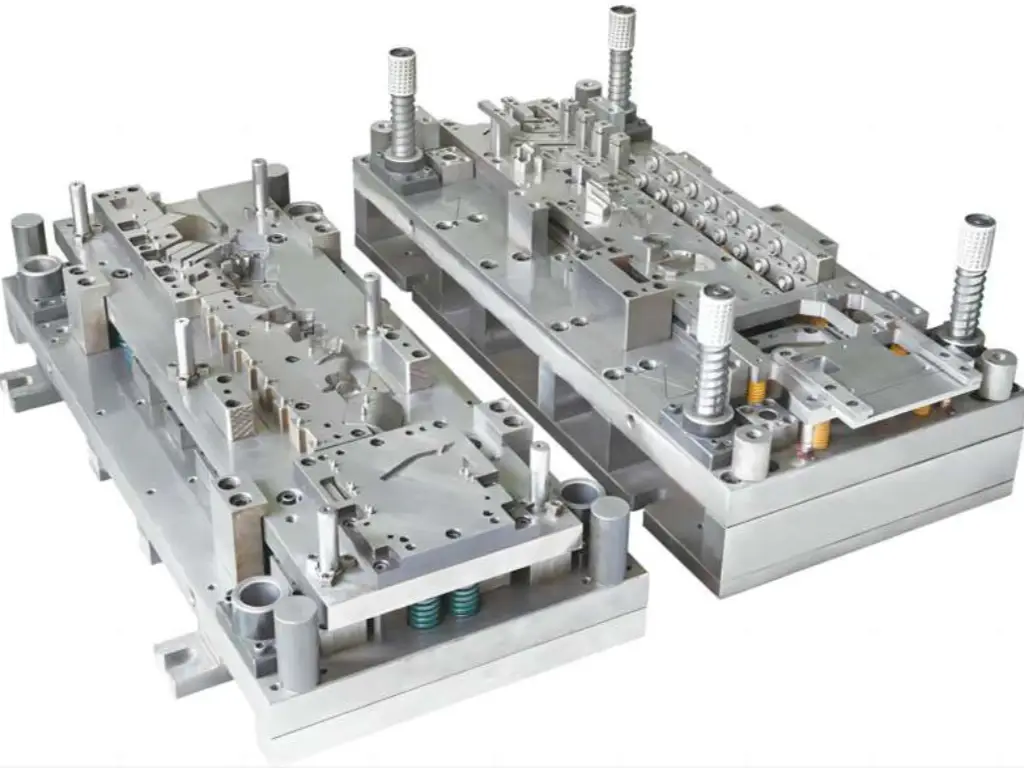

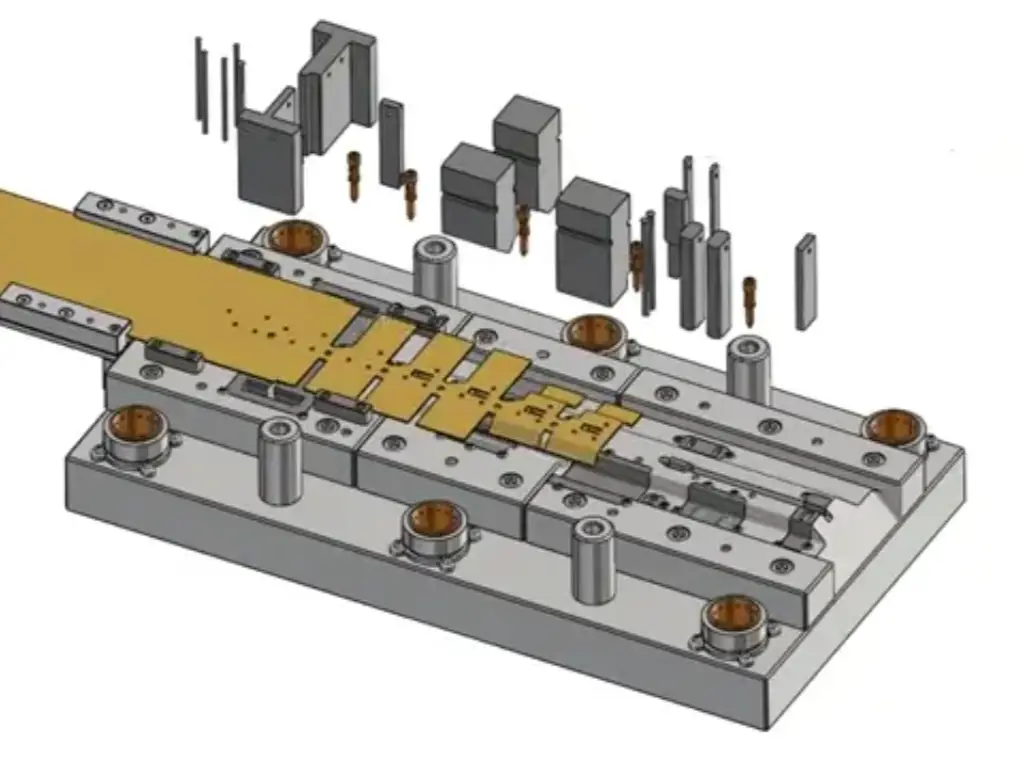

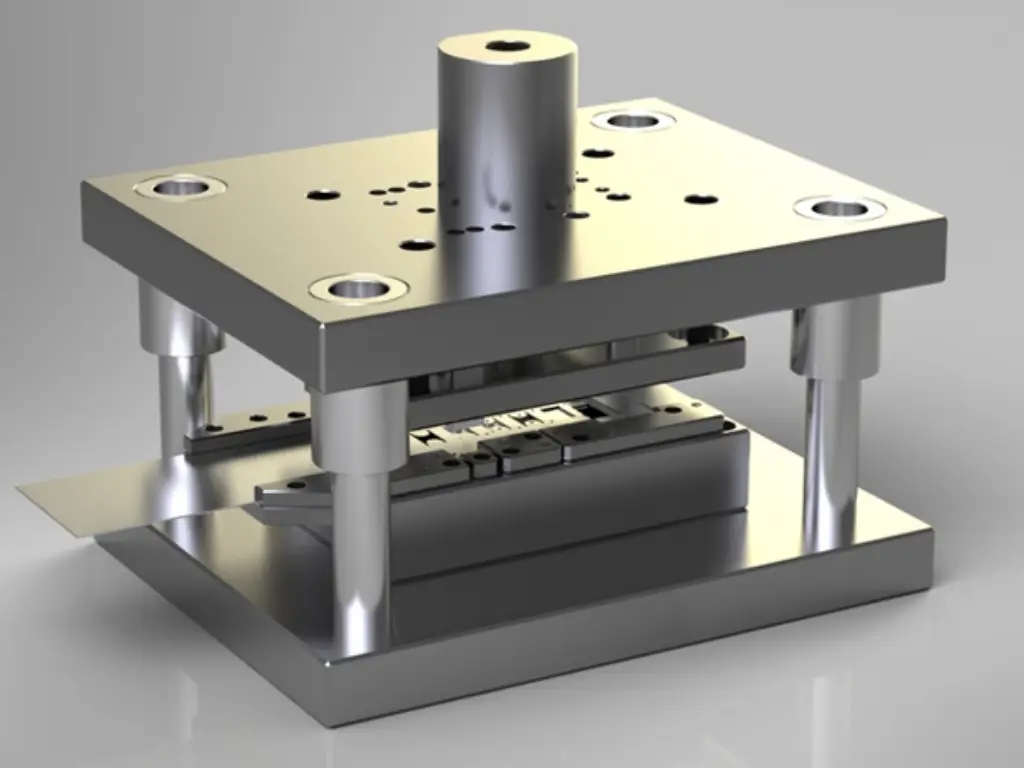

The Anatomy of a Stamping Die

A stamping die is a complex assembly of precision-machined components working in perfect harmony. While designs vary based on the process, most contain several key elements:

- Die Set: The foundation of the tool, consisting of a lower Die Shoe (bolted to the press bed) and an upper Punch Shoe (bolted to the press ram). These are aligned by Guide Pins and Bushings to ensure perfect mating.

- Die Block (or Die Cavity): The lower, stationary part of the tool that contains the female form or cutting edge.

- Punch Plate: The upper part of the tool that holds the punches, which are the male components that perform the cutting or forming.

- Stripper Plate: A plate that surrounds the punch and serves to strip the material off the retracting punch after an operation. This prevents the material from sticking to and lifting with the punch.

- Pilots: Pin-like locators that engage with previously pierced holes in the material strip to ensure precise alignment and progression in a progressive die.

The Inevitable Challenge: Tool Wear and Its Impact

During operation, these die components are subjected to immense forces, friction, and impact with every stroke of the press. This inevitably leads to tool wear, a gradual degradation of the die’s critical surfaces. The primary forms of wear include:

- Abrasive Wear: Caused by hard particles in the sheet metal scratching and gouging the die surfaces.

- Adhesive Wear: Occurs when microscopic welds form between the workpiece and the tool surface under high pressure, which are then torn apart, pulling material from the tool.

- Fatigue: Cracking and chipping of the tool surface caused by the repeated cyclical loading of the press.

This wear is not just a maintenance issue; it directly impacts production quality and cost. A worn cutting edge will produce a larger burr on the part. A worn forming radius will alter the final dimensions of a bend. This degradation leads to parts falling out of tolerance, increased scrap rates, and ultimately, costly production halts for die maintenance or replacement.

Extending Die Lifespan with Custom Replacement Parts

The wear and tear of the critical die components are bound to occur with high-volume production. Conventionally, a major wear of a critical part could be considered as an indicator of the need to replace the whole costly tool, which would result in a considerable downtime and capital cost.

The more intelligent, more sustainable, and much less expensive approach is precision part replacement. This is the area where a dedicated manufacturing partner can be of immeasurable help.

Our engineers at U-Need, who have more than 30 years of experience in the precision machining business, know the tremendous stresses your tooling is subjected to. We are experts in the production of high precision, custom mold and die components that are not only made to meet original specifications, but are made to surpass them. Our core business, 60-70 percent of which is parts to stamping dies, injection molds and cold-heading tooling, is based on addressing the issue of tool wear.

We use the best equipment in the world, including Japanese Takisawa precision lathes, Swiss GF AgieCharmille wire EDMs and Japanese Seibu/Sodick spark EDMs, to provide industry-leading tolerances of up to +/-0.001mm. This accuracy, which is as high as 90 percent more than the industry standard, means that a replacement part of U-Need will fit perfectly and make your die as accurate as it was before.

Moreover, we are not limited by the cost restrictions of the original manufacturer, so we can frequently improve the performance of the part. Through careful choice of better materials, e.g. replacing a standard tool steel with a high performance tungsten carbide or a special PVD coating, we can provide replacement parts with much longer working life than the original. This method of simply replacing the worn-out parts with high-quality parts has the dramatic effect of greatly increasing the total life of your valuable tooling, maximizing your initial investment, and reducing costly production downtimes.

Analyzing the Cost Structure of Die Stamping

It is important to understand the economics of die stamping because it is a high initial investment, very low per-part cost at scale trade-off. The overall cost of a project may be divided into three broad categories.

The Tooling Costs are the first. The most significant individual expense is the design and manufacture of the custom die. The factors that drive this upfront cost are the complexity of the die (a multi-station progressive die is much more costly than a simple blanking die), the precision required (tighter tolerances require more sophisticated machining), the quality of the tool steel used, and the size of the tool in general. This heavy investment should be recouped on the total production volume and therefore the process is most appropriate when large runs are involved.

Total Cost of Ownership (TCO) is important to consider here. Although lower-grade materials may lower the initial tooling cost, they tend to increase the overall costs due to frequent maintenance, downtime, and increased scrap rates. By purchasing a high quality die with better wear resistant parts, e.g. custom made by U-Need, the life of the tool is dramatically increased. The strategy saves long-term costs by making maintenance predictable and reducing the risk of catastrophic failure, so that the die runs efficiently through millions of cycles.

Second are the variable Per-Part Costs which are low when the tool is in operation. This cost is mainly made up of the raw material itself. Any scrap generated (such as the carrier strip in a progressive die) must be included in this cost. To this is added, the machine time, which is an hourly rate of the press, and the labor to set up and watch the machine. These per-part costs are kept very low by high production speeds and automation.

Lastly, the Secondary Operations cost should be taken into account. A finished part is not necessarily a stamped part. The additional processes including deburring, hardness heat treatment, surface finishing (plating, anodizing, or painting), and final assembly contribute to the total unit cost.

Essentially, the economic model of die stamping is characterized by volume. The large initial tooling cost is offset by the fact that the parts are produced in large quantities so that the cost per part is insignificant.

Industrial Applications of Die Stamping Technology

The stamping is a basic manufacturing technology that allows manufacturing in almost all major industrial sectors. Its capacity to manufacture long-lasting, accurate, and economical metal components in large quantities makes it the preferred option of an enormous range of components, including huge automotive panels and minute electronic terminals. The next is a narrowed down examination of what particular products are manufactured through die stamping in these major industries.

Automotive Industry

Die stamping is most used in the automotive industry. The Class-A surface finish and shape of body-in-white (BIW) parts such as doors, hoods, and fenders are stamped. Importantly, the vehicle has a safety cage structure that is stamped to form complex shapes, which offer rigidity and crash energy absorption, and this is done using high-strength steel A/B pillars and chassis rails. Many smaller brackets and engine, suspension and exhaust mounts are also mass produced due to their strength and perfect fit.

Electronics and Telecommunications

This is an industry that uses progressive die stamping to mass produce miniature parts where accuracy is of utmost importance. Stamped metal components such as electrical terminals and pin connectors are used in every circuit board and cable assembly, and are manufactured in the billions. Sensitive microchips are placed in stamped EMI/RFI shields to avoid signal interference. Moreover, internal lead frames which connect a silicon chip to the outside pins of an integrated circuit are a typical example of high precision stamping.

Aerospace and Medical Industries

Die stamping is applied in the aerospace industry to produce thousands of lightweight but strong airframe brackets and clips made of aluminum and titanium alloys that hold wiring and systems in place. Stamped seals and retaining rings of heat-resistant superalloys are necessary in jet engines.

The medical profession requires utmost accuracy and sterility. Both disposable and reusable surgical instruments, including forceps and clamps, are made using stamping. It is also the main way of making the biocompatible titanium casings of implantable devices such as pacemakers, which have to be hermetically sealed and absolutely reliable.

Consumer Appliances and HVAC

The appliances in our houses are constructed using stamped parts. Washing machines, dryers, and refrigerators have large stamped panels as their outer shells. In the interior, stamped components are motor mounts, support brackets, and drum components. Fan blades in HVAC systems are stamped to exact angles to provide the best airflow, and the thin fins that constitute heat exchanger coils are stamped in the millions on high-speed stamping lines.

Die Stamping vs. Other Manufacturing Methods

To make an informed decision, engineers must weigh the benefits of die stamping against other common manufacturing processes.

| Comparison Metric | Die Stamping | CNC Machining | Die Casting | Forging |

| Process Type | Cold-forming sheet metal | Subtractive, cutting from solid block | Molten metal injection into mold | Hot or cold forming of solid billet |

| Unit Cost (High Volume) | Very Low | High | Low to Medium | Medium |

| Tooling Cost | Very High | Low to None | Very High | High |

| Production Speed | Very Fast | Slow | Fast | Medium |

| Lead Time (Initial) | Long (for tooling) | Fast | Long (for tooling) | Long (for tooling) |

| Material Selection | Wide range of sheet metals | Very wide, almost any machinable material | Limited to castable alloys (Al, Zn, Mg) | Limited to forgeable alloys (Steel, Al, Ti) |

| Part Complexity | Good for complex 2D/3D shapes | Excellent for highly complex geometries | Excellent for intricate, net-shape parts | Good for strong, simpler shapes |

| Dimensional Accuracy | Good to Excellent | Excellent | Good | Fair to Good |

| Material Waste | Moderate (e.g., carrier strip) | High (produces chips/swarf) | Low (scrap is easily recycled) | Very Low |

| Best Suited For | High-volume production of sheet metal parts requiring speed and low unit cost. | Prototypes, low-volume production, parts with extremely complex geometries or tight tolerances. | High-volume parts with intricate details and thin walls, especially from non-ferrous metals. | High-strength, safety-critical parts that require superior fatigue resistance (e.g., crankshafts). |

The Future: Smart and Sustainable Stamping

The field of die stamping is not static. Driven by the demands of Industry 4.0 and the need for greater efficiency and sustainability, technology continues to evolve.

Smart Dies and Predictive Maintenance

The future of tooling lies in “Smart Dies.” By embedding IoT sensors directly into the stamping die, manufacturers can monitor critical parameters in real-time.

- Temperature sensors can detect overheating caused by inadequate lubrication.

- Pressure sensors can monitor forming forces to ensure consistency and detect material variations.

- Vibration or acoustic sensors can identify the acoustic signature of a punch beginning to dull or crack, long before it causes a catastrophic failure.

This data feeds into a central system that uses machine learning algorithms to predict when maintenance is needed. This shifts the paradigm from reactive (fixing a broken tool) or preventative (replacing parts on a fixed schedule) to predictive maintenance (intervening at the optimal moment), maximizing uptime and tool life.

The Role of Simulation in Design

Advanced Finite Element Analysis (FEA) software, such as AutoForm or Pam-Stamp, has become an indispensable tool in modern die design. Before any steel is cut, engineers can create a complete digital twin of the die and the stamping process. This simulation can accurately predict:

- Material Flow: How the sheet metal will stretch and compress as it is formed.

- Defects: Potential issues like cracking, wrinkling, or excessive thinning.

- Springback: The tendency of the material to partially return to its original shape after forming.

By identifying and correcting these issues in the digital realm, companies can drastically reduce the time and cost associated with physical tool tryouts and modifications, leading to faster product launches and more robust manufacturing processes.

Stamping Advanced Materials

The push for lightweighting in the automotive and aerospace industries has driven significant innovation in stamping advanced materials like Advanced High-Strength Steels (AHSS) and aluminum alloys. These materials offer incredible strength but are less forgiving to form than traditional mild steel. This has led to the development of new techniques like hot stamping (or press hardening), where the material is heated to a high temperature before being formed and then rapidly quenched in the die. This process creates parts with exceptionally high strength, allowing for significant weight reduction without compromising safety.

Partnering for Success in Custom Stamping

Selecting the appropriate manufacturing process is not the entire battle. A project, particularly one that uses custom parts and requires challenging applications, can only be successful when the right manufacturing partner is chosen. An excellent partner is not only someone who can do parts, they are someone who can provide technical knowledge, quality assurance and a thorough knowledge of the whole lifecycle of your tooling.

In assessing a prospective partner, the following should be considered:

- Technical Expertise: Do they have the experience of giving input on design for manufacturability (DFM)? Are they able to suggest material or process improvements?

- Quality Systems: Do they have certification (e.g. ISO 9001:2015)? Do they have a well-developed multi-step quality control system, starting with the inspection of raw materials and ending with the final dimensional inspection using sophisticated tools such as CMMs?

- Lifecycle Support: What do you do when a tool wears out? Do they provide answers other than quoting a new, costly tool?

An innovative partner realizes that your prosperity is based on the life and efficiency of your capital assets. This is the principle we have based our business at U-Need. We do not just produce replacement die parts. We also use our 30+ years of precision machining experience to develop custom parts to your specialized production equipment so that all elements of your line are optimized to perform. We have a strong after sales service with one year warranty, 24-hour response to problems, and free replacement of any faulty parts.

When you select a partner that can offer this degree of holistic support, you are not purchasing a component, you are investing in a more resilient, efficient, and profitable manufacturing ecosystem.